Epoxy resins & adhesives

Gurit is a leading supplier of high performance epoxy products formulated to meet market and customer needs.

Our innovative approach and expertise in epoxy formulations continues to deliver market leading products for a wide range of market segments. We provide a complete range of formulated products including adhesives, in-mould gelcoats, laminating and multi-purpose systems.

Spabond Adhesives

Spabond™ adhesives offer outstanding performance in high-stress, high-load applications for Marine, Wind Energy and Civil Engineering applications.

Spabond™ 400 Series: structural, high dynamic load applications

Spabond™ 500 Series: specialist substrate and applications

Spabond™ 700 Series: rapid structural adhesives

Spabond™ 800 Series: structural, fast curing for wind blade production

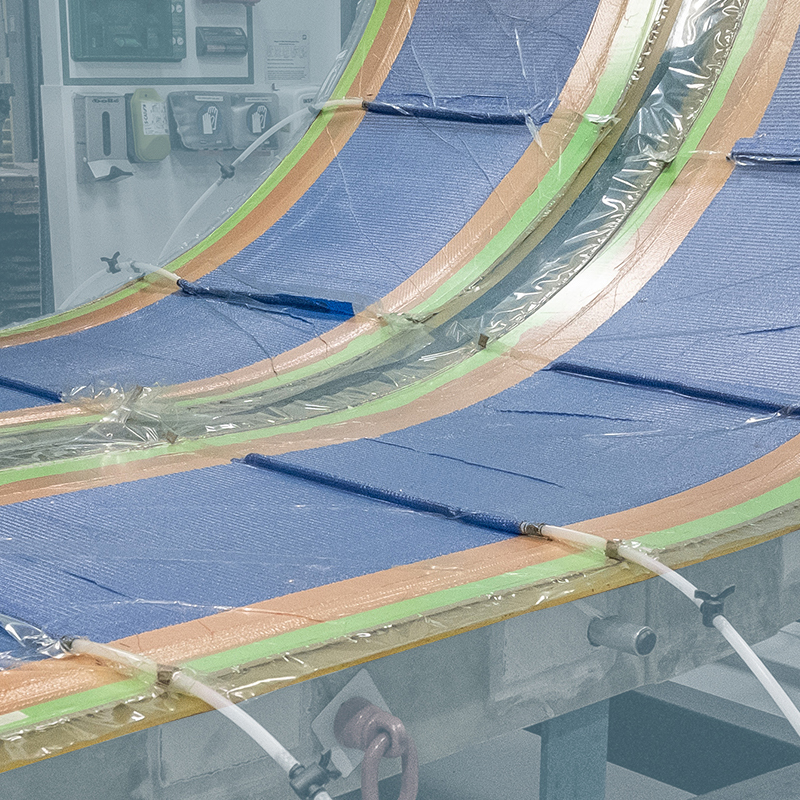

PRIME Infusion

GURIT PRODUCTS/ | MAIN FEATURES | DATASHEETS |

Low Toxicity Epoxy Infusion System Delivers exceptional laminate quality for a range of liquid infusion composite processes. Gurit’s unique fibre wetting technology reduces infusion time and improves laminate quality. |

Ampreg Laminating

The Ampreg™ 3X Series is Gurit’s range of wet laminating systems for the manufacture of large composite structures in the marine, wind and construction industries.

Ampro Multipurpose

GURIT PRODUCTS/ | MAIN FEATURES | DATASHEETS |

Low temperature curing multipurpose system | ||

Clear epoxy laminating resin | ||

Low temperature curing multipurpose system | ||

Low temperature curing multipurpose system |

Reinforcements

Sustainability Report

Creating a Strong Sustainability Platform

Gurit annually reports on sustainability related topics and performance indicators. The Gurit Sustainability Report has been prepared in accordance with the standards of the Global Reporting Initiative (GRI), core option.

Case Study

RECYCLING TEMPERED GLASS PLATES for use in swimming pool filtration systems

The Gurit site in Magog recycles the tempered glass plates used for assembling the moulds in production for SAN structural core foam.

Case Study

Composites beneath Cities

Grupo Navec

This technology offers a safe and effective alternative for pipelines where the execution of actions is extremely complex…