News

SR Structures Partners with Marc Lombard Yacht Design Group to Deliver Lift 45ft Yacht Infused with Gurit PRIME™ 37

SR Structures, a UK developer and manufacturer of advanced composite components, has built a strong reputation for refitting, repairing and building marine vessels.

Their recent delivery of a Lift 45 ft carbon and fiberglass yacht is testament to their expertise in precision engineering, lightweight construction, and high-end finish and was supported throughout using Gurit’s PRIME 37 epoxy infusion system.

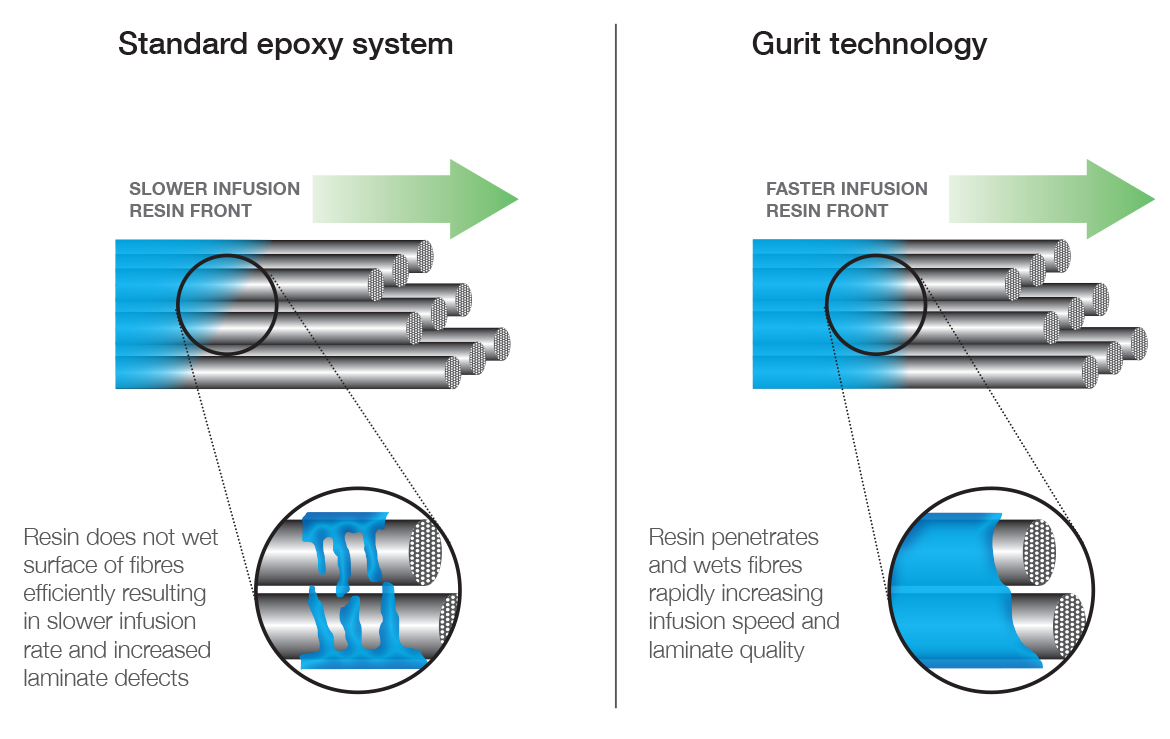

Producing a vessel such as a Lift 45 ft yacht isn’t without its challenges. For SR Structures it meant producing a large, complex fiberglass hull with carbon fiber reinforcements that demanded both exceptional structural performance and an immaculate cosmetic finish. To achieve this, SR Structures needed a very specific type of resin system. One with low viscosity for excellent fiber wet-out, controllable cure characteristics to suit the large mold size, and mechanical properties that would stand up to the demands of high-performance sailing.

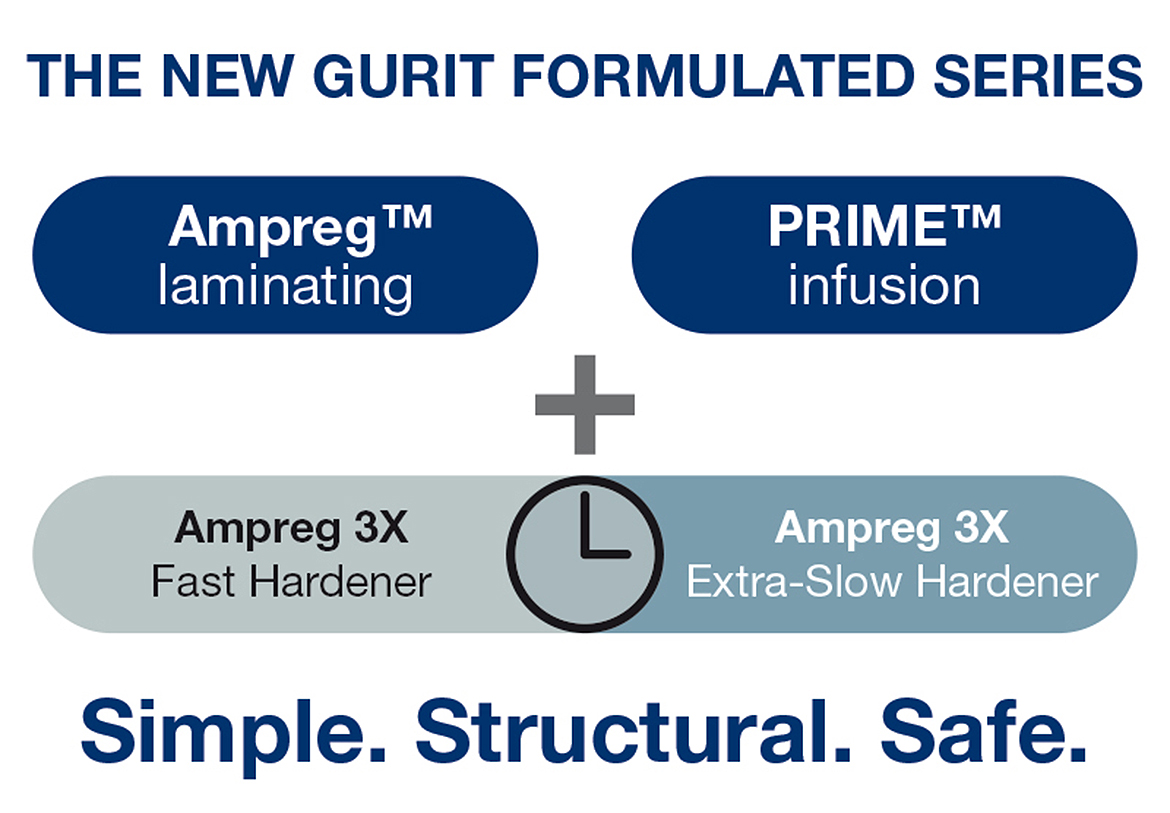

Gurit’s PRIME 37 was the solution they were looking for. Designed specifically for infusion processes, PRIME 37 offers low viscosity for fast, consistent flow, outstanding fibre wetting technology to improve laminate quality, the avoidance of a “sugary phase” due to faster through-cure, and overall improved exotherm control. It has been developed for large, complex mouldings like spars, hulls and reinforcing structures and can be blended with Ampreg 3x Fast and Extra Slow hardeners to achieve intermediate speeds as required.

For this project, the resin’s flow and cure profile allowed SR Structures to achieve complete and even infusion across the yacht’s extensive laminate. The result was a void-free, structurally optimized hull and deck with an exceptional surface finish directly out of the mold. The quality of the finish significantly reduced the need for post-mold fairing and detailing, saving time and cost while maintaining the yacht’s lightweight goals.

By optimizing resin uptake, infusion speed and laminate quality, PRIME™ 37 contributed to a lighter, stiffer structure that translates directly into enhanced speed and handling performance on the water. The controlled process window and reliable cure also provided SR Structures with the confidence to meet tight project deadlines without compromising quality.

PRIME 37 allowed us to hit our weight targets and deliver a yacht that performs as good as it looks

According to SR Structures, PRIME 37 provided not only the performance and finish they required but also the process reliability that gave their build team the confidence to push the boundaries of composite yacht construction.

“The infusion went exactly as planned, and the finish quality straight out of the mold exceeded our expectations,” said Ross Hotchkiss, Managing Director at SR Structures.

He continued, “PRIME 37 allowed us to hit our weight targets and deliver a yacht that performs as good as it looks.”

“Beyond the benefits of the material itself, Gurit’s customer service ensured we had everything we needed to deliver on time.”