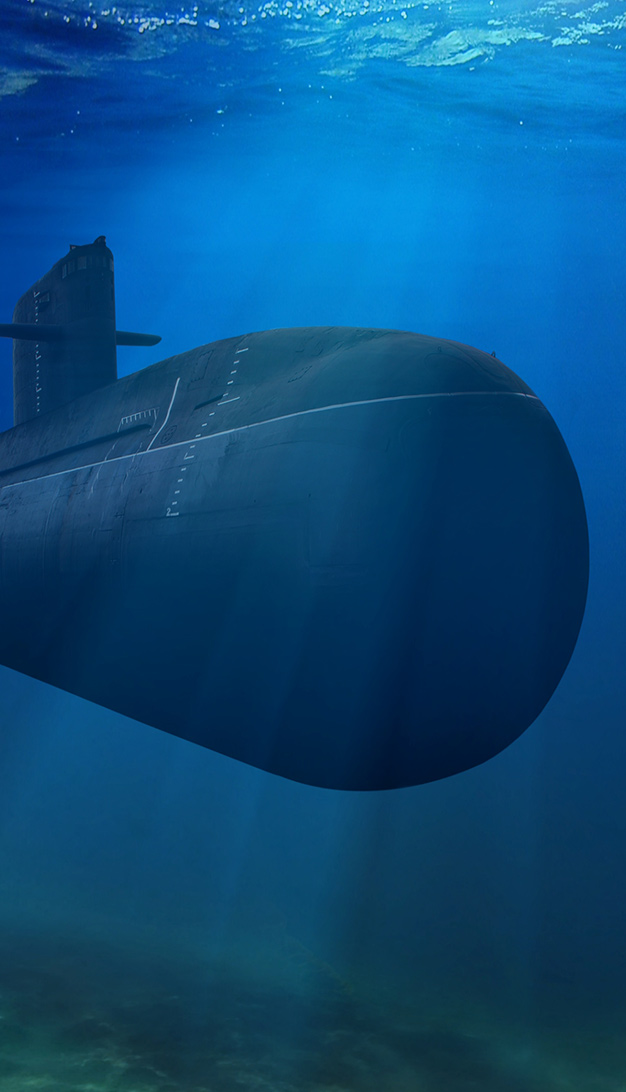

STRENGTH BENEATH THE SURFACE AND BEYOND

HIGH-PERFORMANCE COMPOSITE MATERIALS AND TECHNICAL SOLUTIONS DEVELOPED FOR EXTREME ENVIRONMENTS IN DEFENSE AND SPACE

Gurit manufactures proven structural foam core and prepregs for demanding defense and space applications — from subsea drones and fast craft to radomes, UAVs/UUVs, and launch systems. Combining decades of experience with specialized product families, we enable lighter, stronger and more reliable systems for mission-critical projects.

Discover Our Prepreg Range

DISCOVER OUR CORECELL S-FOAM

DISCOVER OUR CORECELL M-FOAM

Key Benefits

RELIABLE MATERIALS FOR DEMANDING APPLICATIONS

Unmatched Corecell foam and proven Gurit prepregs reliably deliver outstanding mechanical properties at a low weight factor critical for vessels, aerial platforms and space payloads.

DEEPWATER & IMPACT PERFORMANCE

S-foam provides outstanding hydrostatic crush resistance for subsea applications — up to twice the working depth of equivalent-density PVC — enabling greater payload or deeper operation. M-foam offers extremely high impact resistance and slamming performance, while remaining easy to thermoform and machine.

RAPID MANUFACTURE VS PRECISION PERFORMANCE

Our prepreg range supports both high-throughput production and precision-critical use. Products include SE135T-1, SE75-T1, and SE140 — selected to meet varied process and performance needs.

SUPPORT THROUGH THE PROJECT LIFECYCLE

Our engineering and technical teams are experts in developing efficient, optimized structures for defense applications, offering services such as concept designs and feasibility studies, materials development and panel testing, as well regulatory compliance and onsite support.

DURABILITY IN EXTREME ENVIRONMENTS

Materials have been developed for corrosion resistance, fatigue life and long-term reliability in harsh marine, airborne and space environments.

APPLICATIONS WE SERVE

SPACE QUALIFICATION & LAUNCH SYSTEMS

We supply prepregs under qualification programs for launching vehicle structures, supporting the high-reliability needs of the space sector.

FAST CRAFT & SPECIAL FORCES BOATS

Lightweight, high-stiffness structural panels and flotation elements built with Corecell S-foam or prepregs — designed for impact resilience, reduced weight and extended service life.

SENSORS, IMAGING & PAYLOAD STRUCTURES

Corecell S combined with prepregs, and specialized adhesives delivers homogeneous, stiff sandwich panels for sensor mounts, imaging payload bays and structural supports where dimensional stability is key.

SUBSEA & PLATFORMS

Corecell S is used for resilient buoyancy and structural sections in marine patrol platforms, enabling improved payload capacity and increased operational depths compared to PVC.

RADOMES & SPACE STRUCTURES

Precision-grade prepregs (e.g., SE135T-1, SE140) are formulated for radar transparency, high thermal stability and consistent performance under extreme loads — suitable for radome structures, fighter aerospace components and launch vehicle structures.

AERIAL PLATFORMS & UNMANNED AERIAL VEHICLES (UAVS)

Rapid-manufacture prepregs such as SE75-T1 and SE140 are ideal for fast turnarounds in drone production, balancing manufacturability with the required mechanical performance.

SUbsea & Autonomous Underwater Vehicles (AUVs)

Corecell M-foam and S-foam provide the buoyancy, hydrostatic crush resistance and machinability needed for subsea drones and payload housings.

READY TO DISCUSS DEFENSE AND SPACE MATERIAL SOLUTIONS?

EXPLORE CORECELL S-FOAM, M-FOAM, AND OUR SE-SERIES PREPREGS FOR YOUR NEXT MISSION-CRITICAL PROJECT

Technology Highlights

CORECELL FAMILY

S-FOAM: Exceptional hydrostatic crush performance, enabling greater working depth or payload capacity compared to equivalent PVC densities. Ideal for subsea drones and deepwater applications.

- Outstanding hydrostatic crush resistance

- Up to twice the working depth of equivalent-density PVC

- Enables higher payload capacity or greater working depth

M-FOAM: Engineered for extreme slamming resistance, easy thermoforming and excellent machinability for complex shapes and high-impact scenarios.

- Very high performance for extreme, slam-impact applications

- Easy to thermoform and machine

- Ideal for complex shapes and demanding marine environments

PREPREGS (SE-SERIES)

SE135T-1: Precision-grade systems for space and high-performance aerospace where reliability, thermal stability and consistent material behavior are essential.

SE75-T1 / SE140: Optimized for rapid manufacturing and UAV program throughput while delivering reliable mechanical performance.

PROVEN MATERIAL PERFORMANCE AND RELIABILITY

where consistency is key and a wide range of systems to match varied production processes.

SYSTEMs THINKING

Gurit couples core materials and prepregs with proven adhesive systems and processing know-how to create complete solutions — from design advice to material supply — reducing development time and improving manufacturability.

SIGN UP FOR OUR NEWSLETTER

TO STAY UP TO DATE

Get in touch with us to learn more about Gurit and how our solutions can work for you.

© Gurit Services AG, Zurich (CH)