MANUFACTURING Intelligence

Digital solutions for wind blade production

WE ARE READY

FOR THE FUTURE

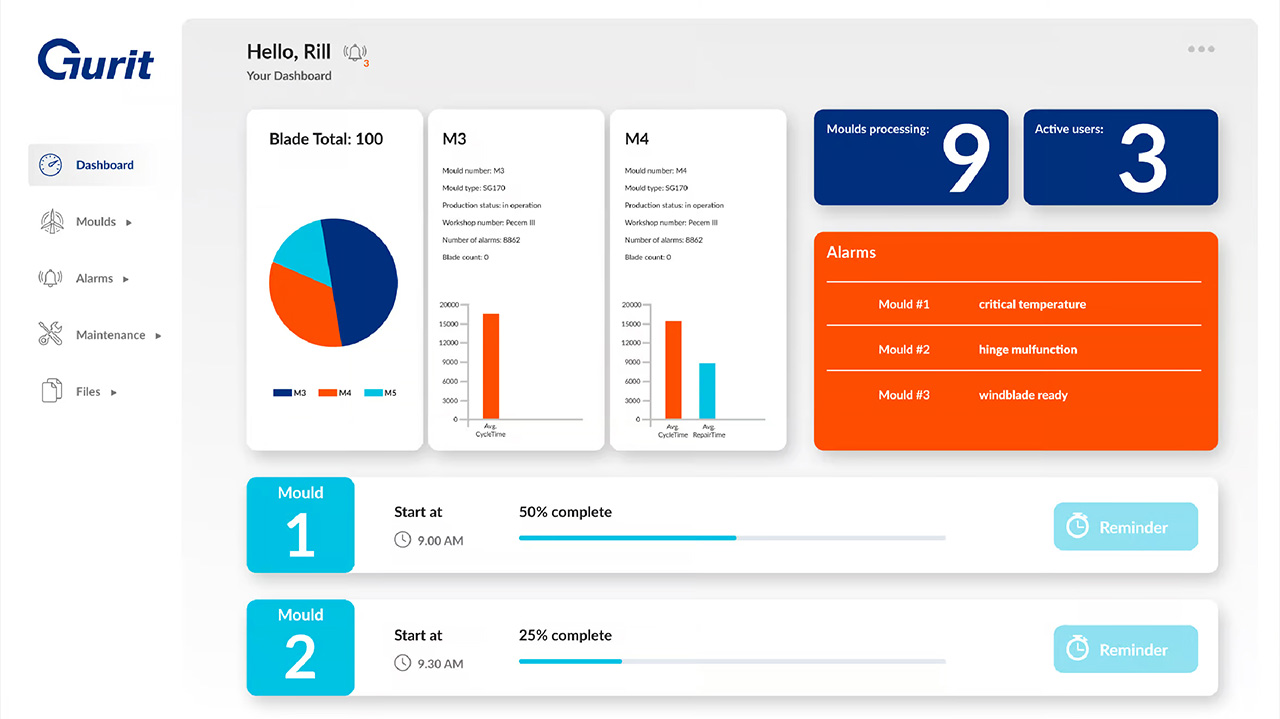

Gurit’s advanced production tools enable significant cost and time savings. This is achieved through real time optimization of the cure cycle; detection of unexpected events; online reporting and mobile push notifications.

DIGITAL SOLUTION APPLICATION

Gurit turns the molds into IoT devices by connecting them to the cloud. Process metrics and quality reports are stored for remote access, displayed on a dashboard or SCADA.

Gurit’s mold-link portal analyses data and develops global production KPI’s. At the factory level the mold’s operation is streamlined through mobile notifications and automated maintenance systems.

Gurit’s proprietary temperature control software is deployed globally and installed in the platforms of the top 3 blade OEM’s.

Gurit Manufacturing System Software Features include

- Surface vacuum SCADA with automatic drop tests and vacuum level control

- Surface thermocouple SCADA with reporting and automatic TG test. Critical areas of the part are monitored to estimate their cure percentage

- Online curing profile adjustment

- Remote /central data warehouse

- Mobile push notifications

- Customizable quality control reports

- Localized composite repair control system

- RFID controlled access

- Dashboard

- Production analytics

FURTHER OFFERINGS FOR WIND BLADE MANUFACTURING

MORE INFORMATION ABOUT OUR WIND ENERGY SOLUTIONS

You want to know more about Gurit’s offering for the wind turbine industry?

Our experts will be happy to support you.

WATCH THE VIDEO TO LEARN MORE ABOUT OUR SOLUTIONS FOR THE WIND ENERGY INDUSTRY

Get in touch with us to learn more about Gurit and how our solutions can work for you.

© Gurit Services AG, Zurich (CH)