Prime™

Structural, high-performance epoxy infusion systems

STRUCTURAL, LOW VISCOSITY EPOXY SYSTEMS FOR VACUUM INFUSION AND RTM APPLICATIONS

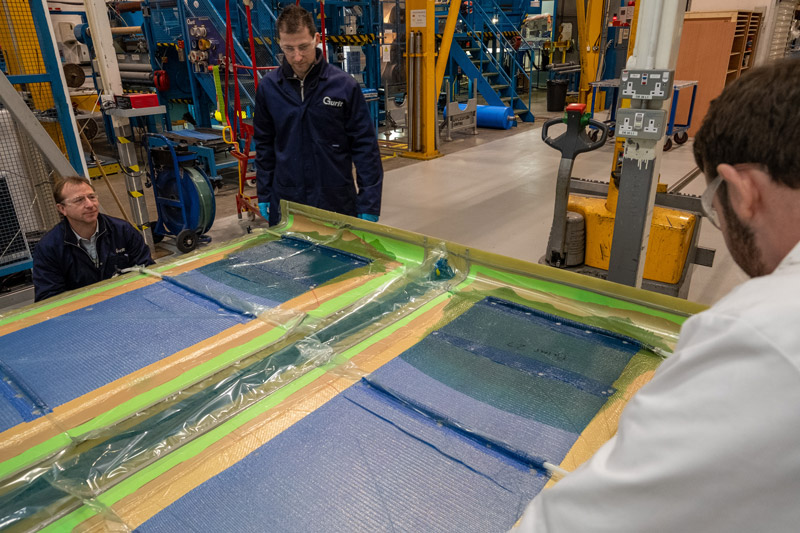

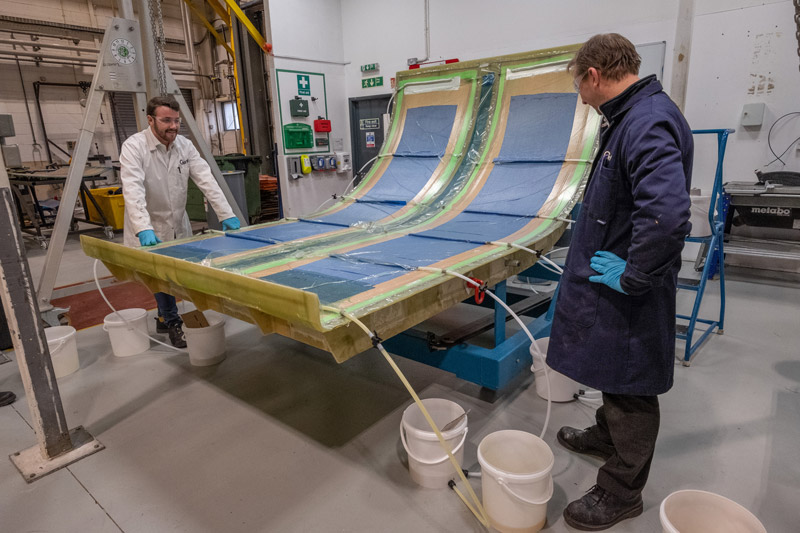

Combining precision processing, versatility, and exceptional performance, PRIME epoxy systems are trusted for the infusion and manufacture of high-quality composite components. Designed for use across wind energy, marine, automotive, and industrial sectors, PRIME delivers consistent results through controlled processing and outstanding mechanical performance.

Why choose Prime

PRIME epoxy infusion systems have been used successfully for over 20 years and today are at the forefront of the development of liquid epoxies for “under the bag” infusion processes.

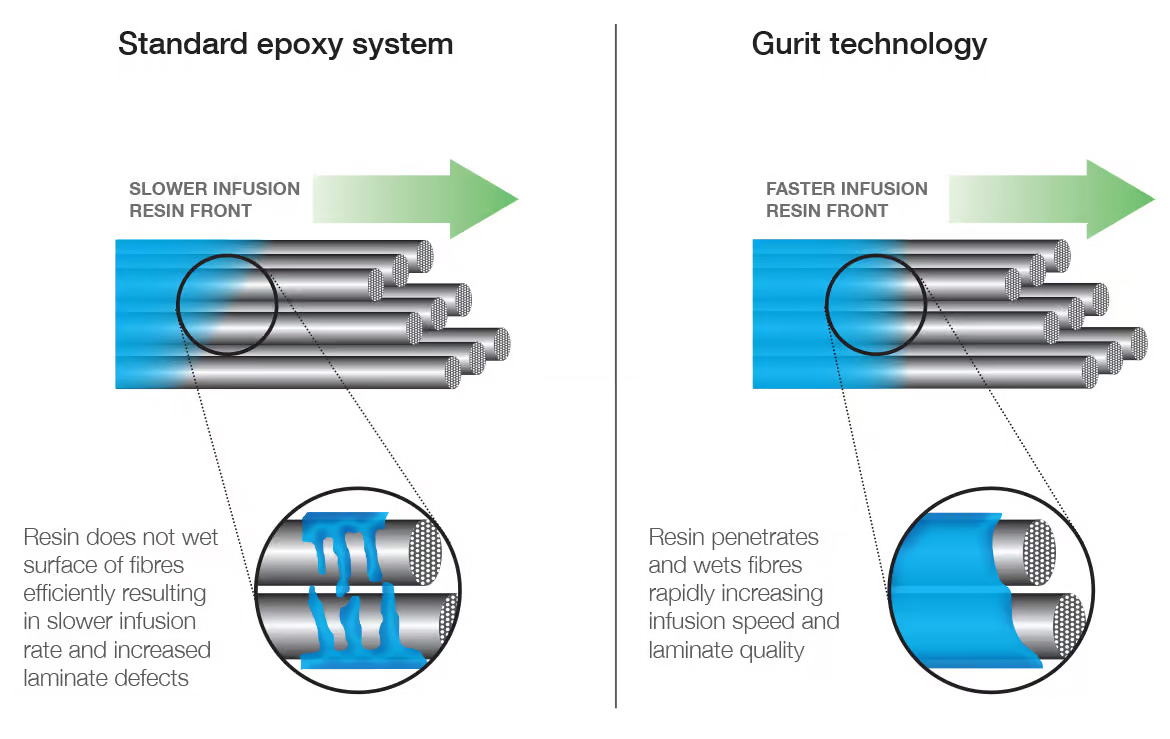

Engineered to make composite infusion simpler, cleaner, and more efficient, PRIME offers low mixed viscosity, excellent fiber wetting characteristics, and reliable cure profiles, ensuring high laminate quality and repeatable performance.

The systems are compatible with a variety of infusion processes including SCRIMP™, RIFT and VARTM and are available with a range of hardeners to suit different component sizes and production speeds.

PRIME systems also feature improved environmental credentials, with bio-based content as standard and options for higher bio-content resins to support reduced carbon footprint manufacturing.

Prime is Ideal for

Developed for precision and performance, PRIME systems are suitable for a wide variety of composite infusion and tooling applications. Whether manufacturing large marine hulls, high-performance wind turbine blades, or industrial components, PRIME provides the processing reliability and strength demanded in high-specification composites manufacturing.

Resin infusion and vacuum-assisted resin transfer molding (VARTM)

SCRIMP™ and flexible tooling processes

Structural and sandwich composite manufacture

Marine, wind energy, automotive, and industrial applications

High-quality, print-resistant molds and components

Infusion processes requiring extended working time

or elevated Tg

PRIME 37 BIO-BASED, LOW TOXICITY INFUSION SYSTEM

PRIME 37 has been developed to deliver exceptional laminate quality for a range of liquid infusion composite processes. Gurit’s unique fiber wetting technology reduces infusion time and improves laminate quality.

The cure characteristics of PRIME 37 have also been optimized:

-

- Mixed viscosity remains lower for longer

- Faster through-cure, avoiding a low-strength “sugary” phase

- Improved exotherm control

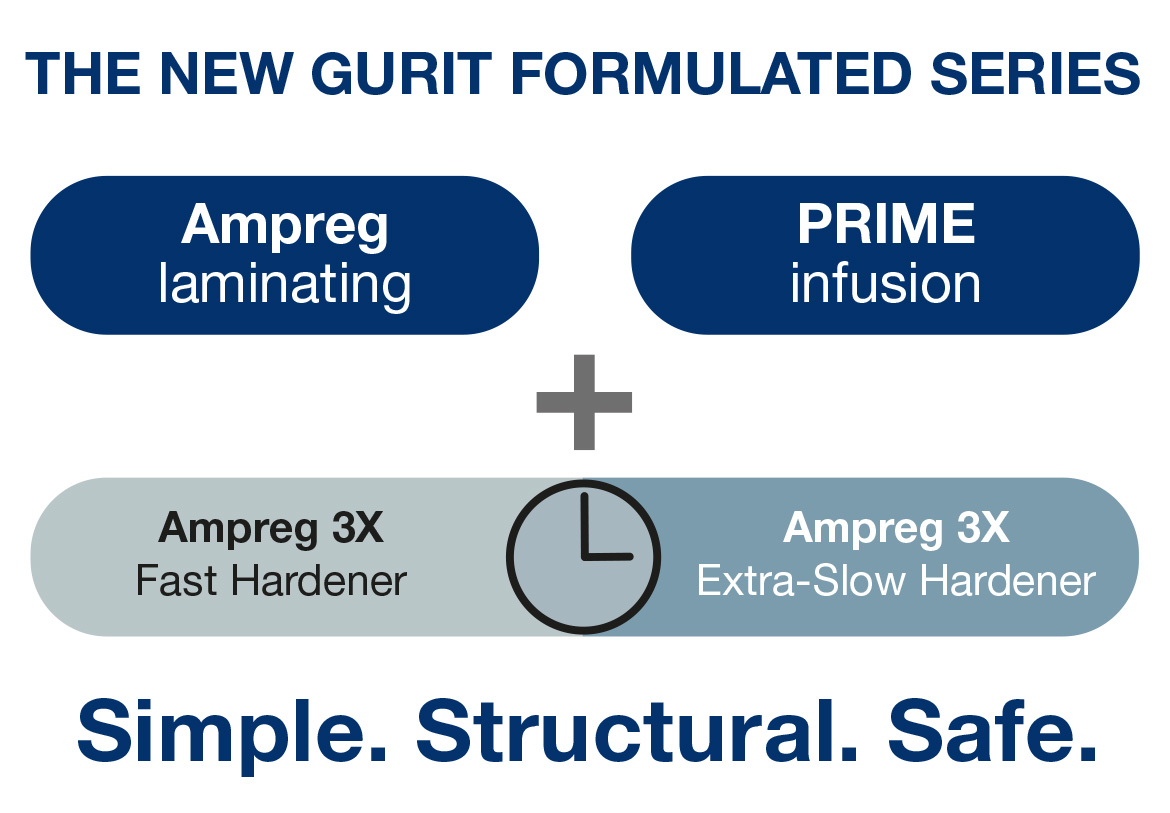

PRIME 37 is Lloyd’s certified and is produced with bio-based content as standard. By using the award winning Ampreg 3X low toxicity hardeners, PRIME 37 allows customers to take advantage of the blendable hardener speeds which can be tailored to suit each application. PRIME 37 is a premium epoxy infusion system incorporating bio-based materials as standard, with options for up to 38% certified bio-content. It provides excellent fiber wetting, long open time, and a wide selection of hardeners to match any mold size or processing speed.

PRIME 38 UV Resistant Epoxy Infusion System

PRIME 38 is a low-viscosity epoxy resin system designed to deliver outstanding performance in applications where surface finish and colour stability are critical. Developed with enhanced resistance to UV yellowing, PRIME 38 ensures long-term clarity and appearance, making it ideal for visible composite structures and high-quality molded parts.

The cure characteristics of PRIME 38 have also been optimized:

-

- Extended gel time at room temperature, ideal for large component manufacture

- Excellent thermal stability with elevated glass transition temperature (Tg)

- High clarity and low-yellowing formulation for improved cosmetic finish

PRIME 38 is DNV-approved and formulated using Gurit’s low-toxicity chemistry for safer handling. When combined with the PRIME High Tg Hardener, it delivers superior thermal and mechanical properties across a wide range of liquid infusion and low-pressure RTM applications.

Products

Prime 37

Ampreg 3X Fast Hardener

MIXED VISCOSITY

510 cP

150G GELTIME

1/2 hour

MIX RATIO

100:29 (parts by weight)

CURED TG

Up to 75°C

CERTIFICATIONS

Lloyd’s Register

DNV (Pending)

Prime 37

Ampreg 3X Standard Hardener

MIXED VISCOSITY

345 cP

150G GELTIME

1 hour

MIX RATIO

100:29 (parts by weight)

CURED TG

Up to 75°C

CERTIFICATIONS

Lloyd’s Register

DNV (Pending)

Prime 37

Ampreg 3X Slow Hardener

MIXED VISCOSITY

245 cP

150G GELTIME

4 hours

MIX RATIO

100:29 (parts by weight)

CURED TG

Up to 75°C

CERTIFICATIONS

Lloyd’s Register

DNV (Pending)

Prime 37

Ampreg 3X Extra-slow Hardener

MIXED VISCOSITY

150 cP

150G GELTIME

10 1/2 hours

MIX RATIO

100:29 (parts by weight)

CURED TG

Up to 75°C

CERTIFICATIONS

Lloyd’s Register

DNV (Pending)

Prime 37

PRIME High Tg Hardener

MIXED VISCOSITY

245 cP

150G GELTIME

5 hours

MIX RATIO

100:25 (parts by weight)

CURED TG

Over 100°C

CERTIFICATIONS

DNV

Prime 38

PRIME High Tg Hardener

MIXED VISCOSITY

245 cP

150G GELTIME

5 1/2 hours

MIX RATIO

100:24 (parts by weight)

CURED TG

Up to 120°C

PRIME is the ultimate solution for those looking for a reliable, high-performance epoxy infusion system

Discover how PRIME can support your next project or inquire about becoming a distributor.

Committed to sustainability

Our sustainability progress has once again been recognized by EcoVadis who awarded us a Gold Medal for the second year running. We are committed to collaborating with suppliers across the value chain to ensure that we continue to bring sustainable innovation to our products, and our customers.

Gurit Epoxy Resins & Adhesives now contain Biomaterials as standard, with the ability to reduce CO2 by up-to 32% over non-bio options.

- No compromise on performance

- No price premium

- Reduced CO₂ footprint as standard

Downloads

Get in touch with us to learn more about Gurit and how our solutions can work for you.

© Gurit Services AG, Zurich (CH)