Corecell™ S

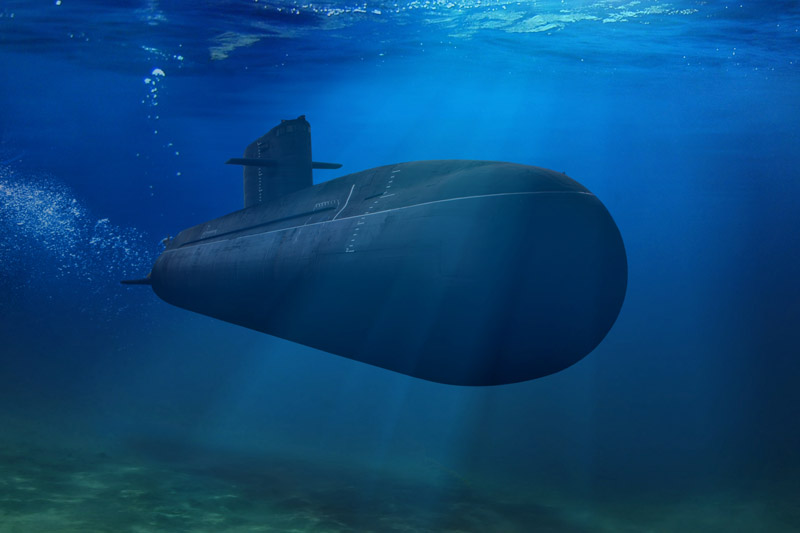

Reliable Buoyancy. Extreme Depths.

Structural SAN foam core for subsea and offshore applications

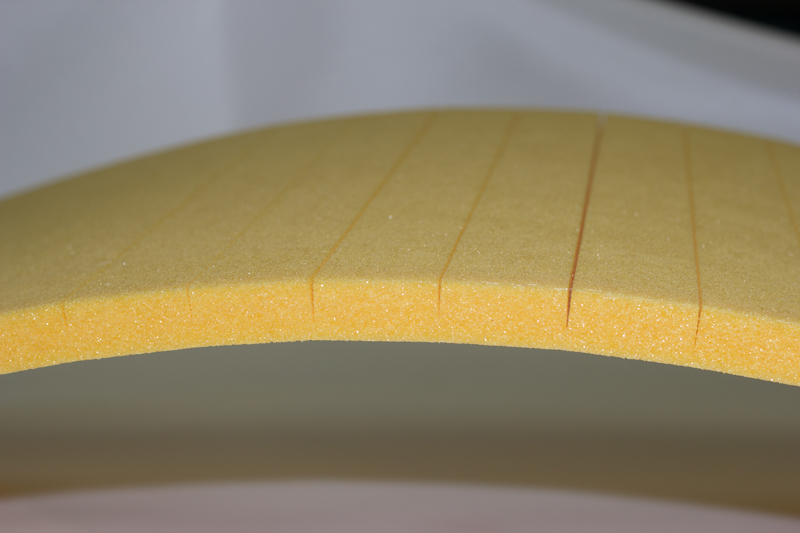

Gurit Corecell S is a high-performance SAN foam developed specifically for use in subsea buoyancy systems, delivering exceptional hydrostatic crush strength, minimal buoyancy loss, and long-term reliability at depth. With an ultra-fine cell structure, high water resistance, and outstanding chemical and thermal stability, it is a lower density high-performing alternative to resin-based syntactic foams.

Gurit Corecell S is an ideal choice for components such as subsea buoyancy or storage units, diving bells, ROVs and impact protection structures. It is easy to machine, is thermoformable, and is suitable for use with a variety of processing techniques, offing a high degree of versatility and suitability for complex shapes.

Key Benefits of Corecell S

High Hydrostatic Crush Strength

Can withstand up to 27 MPa hydraulic crush pressure, maintaining buoyancy and structural integrity

Lower Density Than Syntactic Foams

Delivers equivalent buoyancy at lower density (200 – 450 kg/m³), offering substantial weight savings and easier handling

Low Water Absorption

Closed-cell structure ensures high water resistance, ensuring minimal changes to buoyancy due to seawater penetration

Chemical & Thermal Resilience

Resists degradation in seawater and hydrocarbon environments; offers excellent dimensional stability and insulation properties across a broad temperature range

Low Resin Absorption

Smallest cell size of Corecell range, absorbing minimal resin during lamination and minimising weight gain

Excellent Machineability

Ultra-fine cell size and inherent toughness enable precision cutting, drilling, routing, and thermoforming

Processing and Compliance

- Compatible with epoxy, polyester, and vinyl ester resin systems.

- Processes include infusion, hand lamination, and thermoforming.

- Available in sheet or pre-cut kits, with standard finishing options (plain, pinhole, and vacuum-infusion cut) for maximum flexibility in production.

- Full DNV approval in progress. Extensively tested for dimensional, thermal, and chemical stability.

Available Densities and typical ranges

Grade

Density

Application Depth (approx.)

Corecell S210

210 kg/m3

Shallow subsea structures / floatation devices

Corecell S250

245 kg/m3

General marine and subsea buoyancy

Corecell S270

270 kg/m3

General marine and subsea buoyancy

Corecell S315

315 kg/m3

Mid-depth ROV and instrument housings

Corecell S350

350 kg/m3

Mid-depth ROV and instrument housings

Corecell S400

400 kg/m3

High-load buoyancy and deep subsea equipment

Corecell S450

450 kg/m3

High-load buoyancy and deep subsea equipment

Typical Applications

ROVs and AUVs (military, research, inspection)

Buoys and subsea floatation modules

Underwater structures and storage units

Diving bells and impact protection structures

Offshore wind and oil installation components

Civil and recreational projects (bridges, floating platforms, sports equipment)

Setting the standard for subsea applications with SAN technology

Corecell S extends Gurit’s proven SAN chemistry into deep water applications — offering a tough, lightweight, and cost-effective solution for reliable buoyancy at depth. It complements Corecell M and Corecell I within the Gurit Corecell family to cover the entire range from marine structures to industrial and subsea systems.

Downloads

Product Brochures

Processing Guides

Datasheets

Gurit Standard Finishes

Get in touch with us to learn more about Gurit and how our solutions can work for you.

© Gurit Services AG, Zurich (CH)