Stretch Wars: The Rise, Fall, and Legacy of Helanca

Innovation has been at the heart of Gurit and its original parent-company, Heberlein, from the beginning. The Group’s first patent, Helanca, became a global success and paved the way for a future in performance materials.

Before World War II, rubber was the dominant material used in women’s girdles and foundation garments. But with the war effort demanding vast quantities of rubber for military use, its role in fashion sharply declined. Scientists and textile innovators knew a replacement was needed – something more modern, versatile, and less reliant on limited natural resources.

Enter Nylon, introduced by DuPont in 1938, a synthetic marvel that marked a new era in fabric technology. But even before that milestone, another innovation was taking shape across the Atlantic.

The Birth of Helanca

In 1931, Rudolph H. Kägi invented what would become known as the Helanca process, initially applied to viscose fibers. A few years later, he sold the manufacturing rights to Heberlein & Co., who helped develop and commercialize the product on a global scale.

After extensive research and development, Heberlein (who became Gurit-Heberlein and then Gurit) patented a three-step texturizing process, in which the fiber is twisted, heat set and then untwisted as it cools, that gave synthetic yarns a natural, elastic feel.

The result? A crimped, springy yarn that could be woven alone or blended with other fibers, producing fabrics with improved stretch and comfort.

By 1937, Heberlein began manufacturing Helanca stretch nylon and wool, first used in ski pants, a perfect match for the demands of cold-weather, active wear. After World War II, interest in stretch fabrics surged, and Helanca became a global success.

At its peak, the Heberlein Group employed over 5000 people, held exclusive global licensing rights, and operated its own custom machinery and research division – a rarity in the textile industry at the time.

The Synthetic Fiber Bubble Bursts

By the late 1960s, however, the synthetic fiber market was teetering on the edge of collapse. A global synthetic fiber crisis took hold, driven by a mix of economic, industrial, and market forces, mainly involving overproduction of synthetic fibers, falling prices, and rising competition.

The crisis triggered massive industry restructuring – with companies merging, downsizing, or shutting down entirely. For Heberlein, this meant shrinking operations and gradually losing global visibility for the Helanca name. Though it survived in niche markets, notably in Brazil where “helanca” is still a generic term for stretch fabrics, its prominence faded. Eventually, Heberlein sold much of its remaining Helanca-related business to Saurer in 2005, closing a historic chapter in textile innovation.

What Is Helanca Exactly?

Despite being commonly mistaken for a fiber, Helanca is technically a process and a brand name for a type of yarn. The original Helanca process involved texturizing synthetic fibers like nylon (polyamide) or polyester by crimping or coiling them to introduce elasticity. The result is a stretchy, elastic yarn, but it depends on an existing base fiber – Helanca itself is not a fiber.

By contrast, Lycra, developed by DuPont in 1958, is a synthetic fiber. Also known as elastane (or spandex in the U.S. and Canada), Lycra was created specifically to replace rubber in garments. It is made from polyurethane, a type of elastomer, and has exceptional stretch and recovery, able to extend 5 to 8 times its original length and snap back to form without damage.

Whereas Helanca is a yarn made through a process, Lycra is a performance fiber in itself.

The Shearwater catamaran is one of the UK’s most enduring and technically progressive multihull classes. First designed in 1956, the Shearwater celebrates its 70th year as a class, from cold-moulded timber to today’s full carbon, foam-cored epoxy structures.

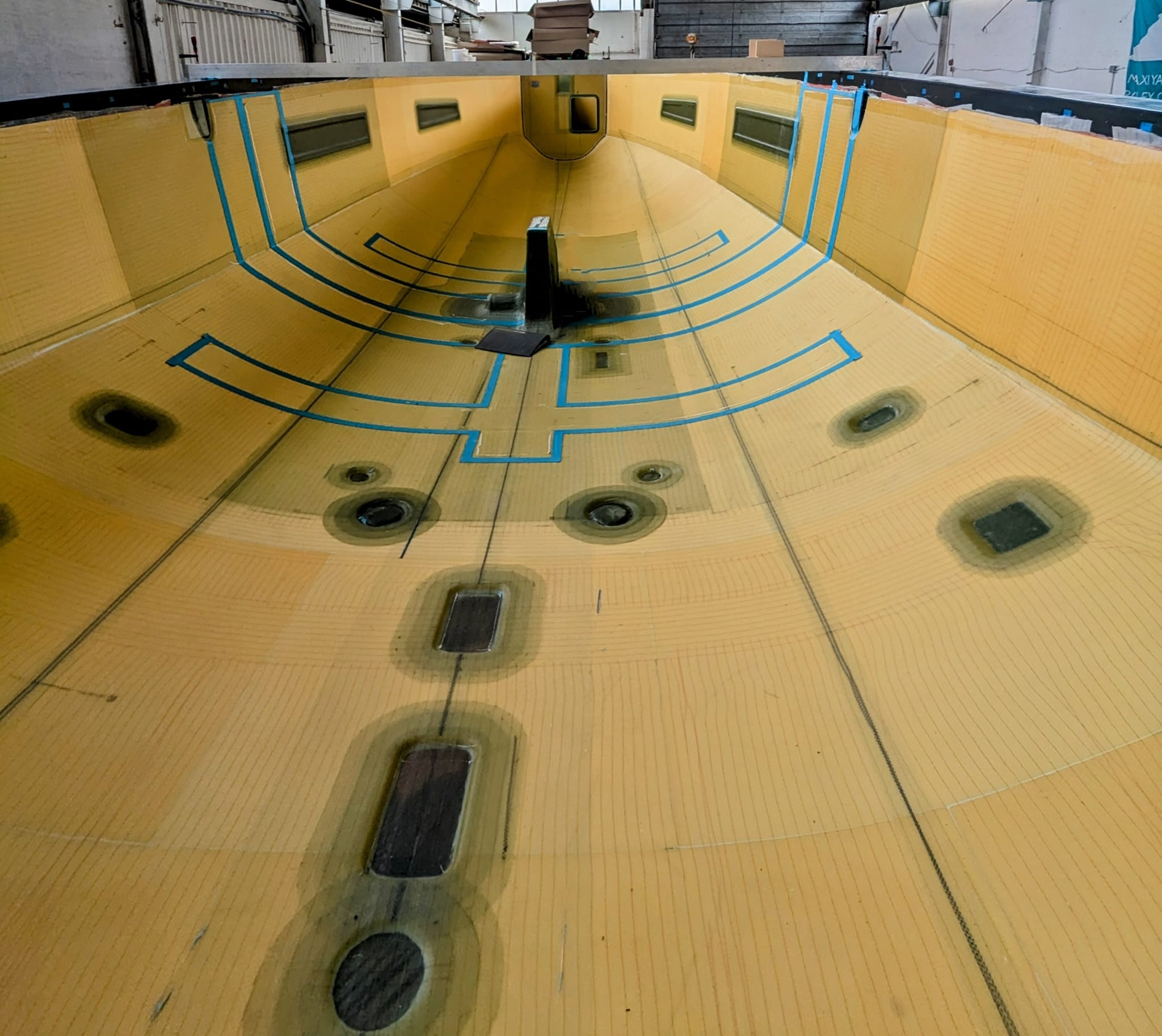

That evolution continues with the latest Shearwater racing catamaran built by Zest Boatworks, under the direction of owner and boatbuilder Pete Jary. Built using advanced composite materials from Gurit, the boat represents the cutting edge of Shearwater design while remaining firmly rooted in the class’s rich heritage.

The unfinished boat will be on display at the RYA Dinghy and Watersports Show 2026 on 21-22 February, offering a rare opportunity to see the structure and materials behind a modern high-performance racing catamaran.