Transportation

LIGHTWEIGHT MATERIALS FOR A SMOOTHER RIDE

Advanced composite materials for various applications within the transportation sector contribute to safety and cost savings. For example our PET structural core material and a range of laminating and adhesive products enable cost-effective production cycles, safety, FST-properties, low toxicity and energy saving throughout the lifecycle of the end product.

Find out more in our case studies and learn about how we serve the transportation sector from cooling trucks to high speed trains, subways or hyperloop applications.

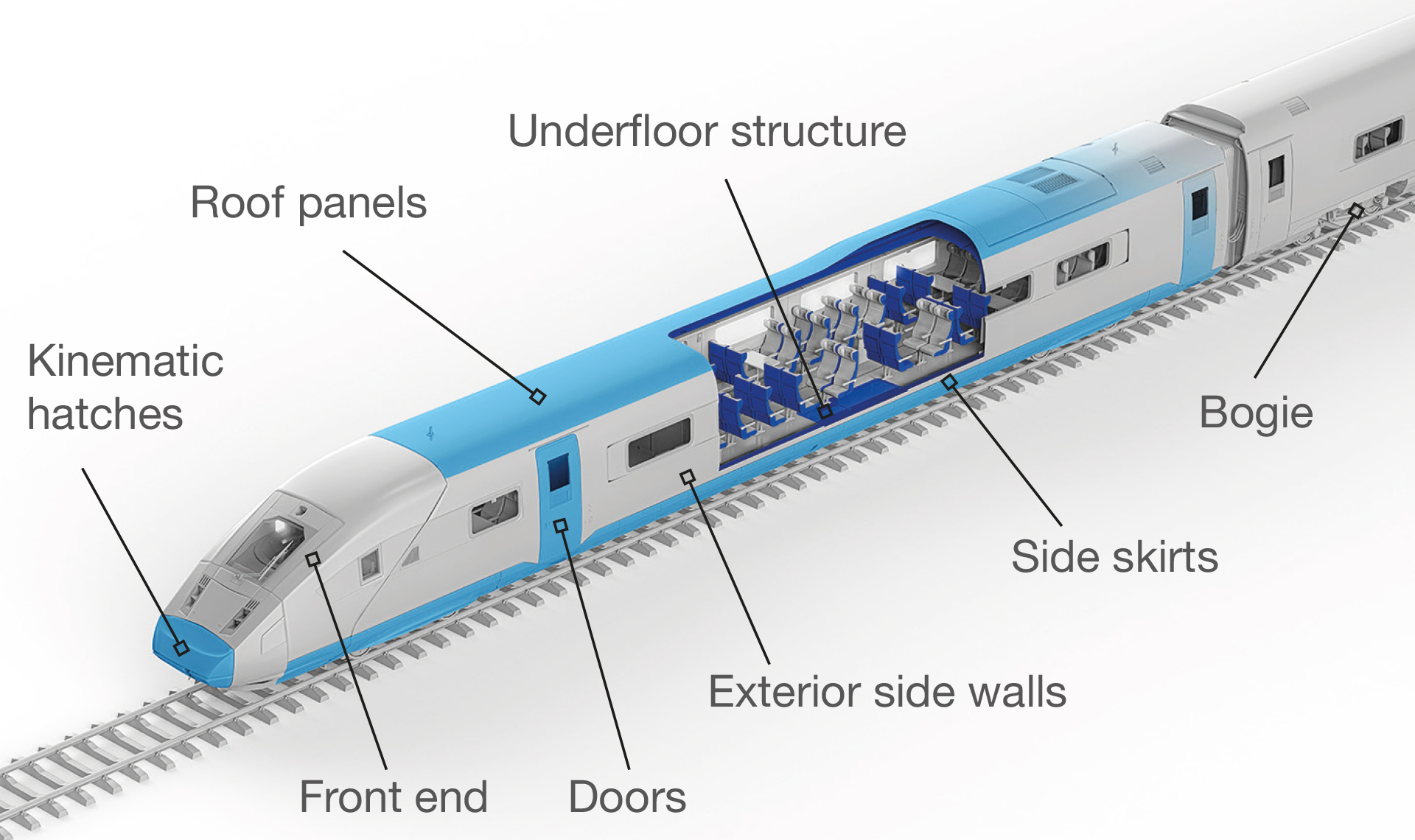

Lightweight composites for Rail

Advanced composite materials supplied by Gurit offer large potential for superior lightweighting vs. traditional materials whilst fulfilling the highest demands in fire protection, meeting the European Standard EN 45545. Gurit’s stronger, more durable and easy to clean materials translate into lower maintenance costs over the whole life span

Composites for Rail

Learn more about Gurit’s competences and offerings for high speed trains, subways and other means of mass transportation.

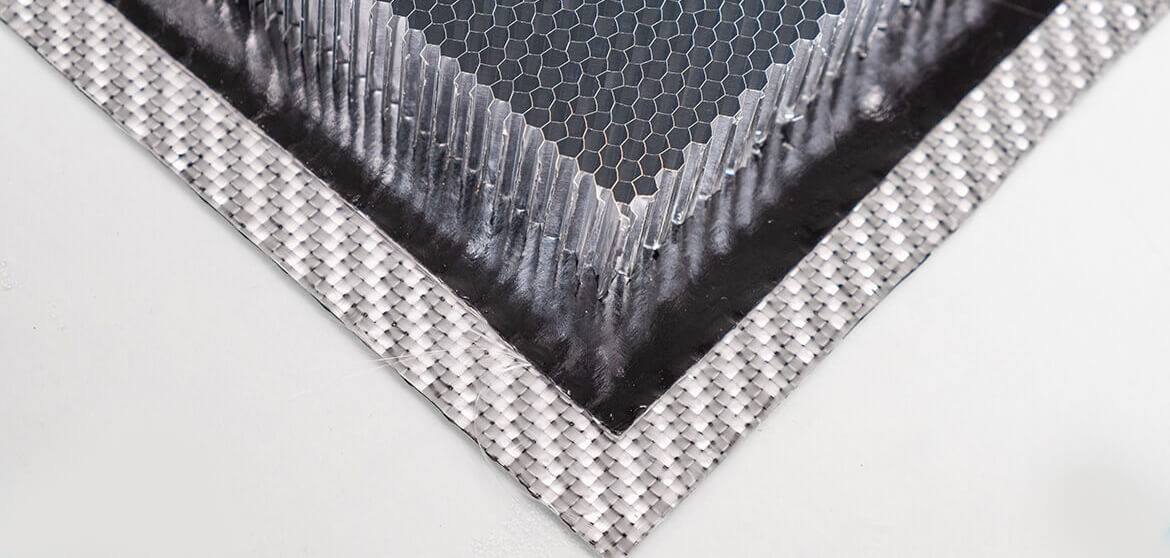

Gurit SPRINT™ Prepregs

SPRINT™ is an advanced prepreg with 2 layers of reinforcements. This innovative material helps high speed trains to become faster and more energy-efficient.

Product applications

Comprehensive offering with both epoxy and phenolic chemistries for balancing fire and structural performance.

“Feedback from customers in China working with Gurit SE 130FR SPRINT™ solution to make rail components has been exceptional, from the excellent material handling properties to the flexible manufacture process; parts can be cured in oven or press under 85°C, resulting in significant lightweighting and low total cost.”

Gurit’s range of Advanced Composite Materials for the Rail Industry

Gurit has extensive knowledge of fire safety requirements for the rail industry. Tried and tested laminates have been manufactured for the following applications using the products shown – contact us for further details.

R7 - EXTERIOR R10 - FLOORING

product selector

High performance, proven light-weighting capability, cost effective products for industrialised production methods.

NAME APPLICATION CURE RANGE PROCESS TG RANGE EN45545-2 CLASSIFICATION* Exterior / structural 85 - 120°C OoA, Press, Autoclave 100-130°C R1 & R7: HL2; R10: TBA Exterior / structural N/A OoA, Press, Autoclave 67-81°C R7: HL2; R10: HL2

*Dependent on laminate configuration

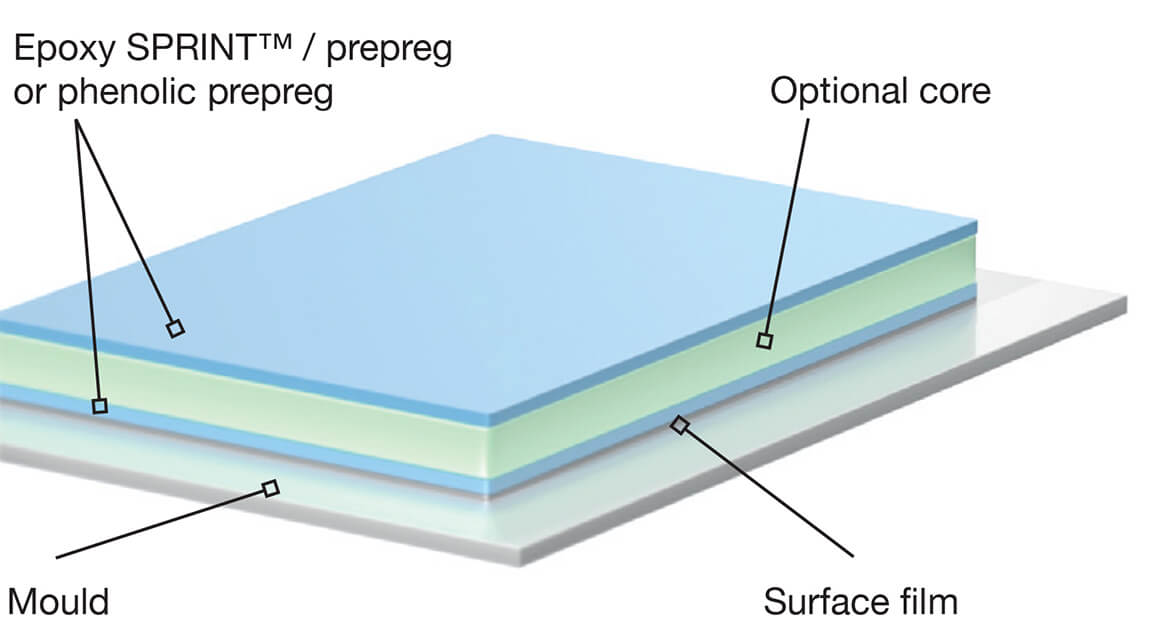

Panel Construction

Typical panel construction for Rail with epoxy SPRINT™ or phenolic preimpregnated fabrics (prepreg):

case studies

Case Study

Hyperloop

The future of high speed transportation

A Hyperloop is a sealed tube or system of tubes through which a pod transporting passengers or freight may travel free of air resistance or friction, allowing people or objects to travel at high speed while being very efficient.

Case Study

Conquering the sun

Solar challenge Australia

For over 30 years the Bridgestone World Solar Challenge has inspired student teams to push the limits of technology to build a vehicle to travel across the Australian outback powered by the energy of the sun. Gurit is pleased to have been supporting the Western Sydney Solar Team with materials and in designing and optimising their latest vehicle, “Unlimited 2.0”.

Case Study

Electric ferry

Lightweight composites for an electric passenger ferry

Electrification of transport is one of the key ways that we will be able to reduce carbon emissions. High speed ferries, an integral part of the transport network of many cities pose a particular challenge but also massive potential in reducing emissions. When it comes to electric propulsion reducing the weight of the vessel is paramount.