Core Material Kitting for Wind Blades

CUSTOMIZED CORE KITS FOR THE GLOBAL WIND POWER INDUSTRY

Gurit delivers advanced, customised, competitively priced core kits to the wind power industry, through a simplified global supply chain.

We are fully transparent in terms of material and kitting costs, which allow our clients to make the right decisions regarding sub-suppliers, core materials, specifications, and requirements. No matter the specific need, our engineers are ready to create and deliver the perfect kit.

UNRIVALLED EXPERTISE THROUGH 30+ YEARS OF EXPERIENCE

For over 30 years we have been supplying core kits to the industry, which has allowed us to effectively optimise our processes, to maximize efficiency and output.

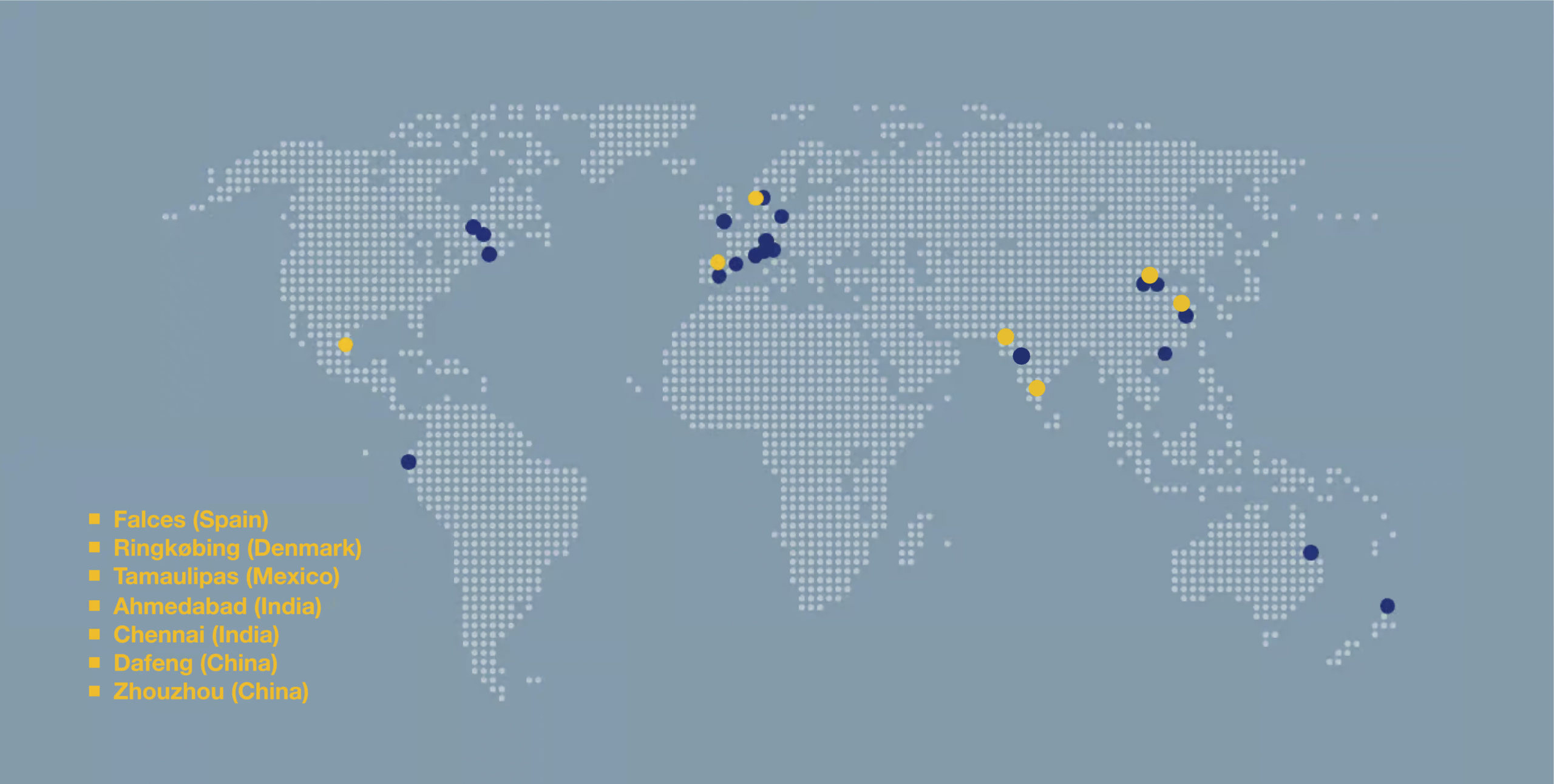

With manufacturing sites and presence in Americas, EMEA, and APAC, you get a truly global kitting partner driven by continuous improvement, flexibility, and transparency.

gurit’s global Kitting footprint in major wind turbine blade production centers

Achieving the Perfect Fit

Today’s auction-driven industry requires the optimization of cost in every step of the manufacturing process. As the global market leader, we ensure short lead times and give manufacturers freedom to choose and produce cost-competitive turbines.

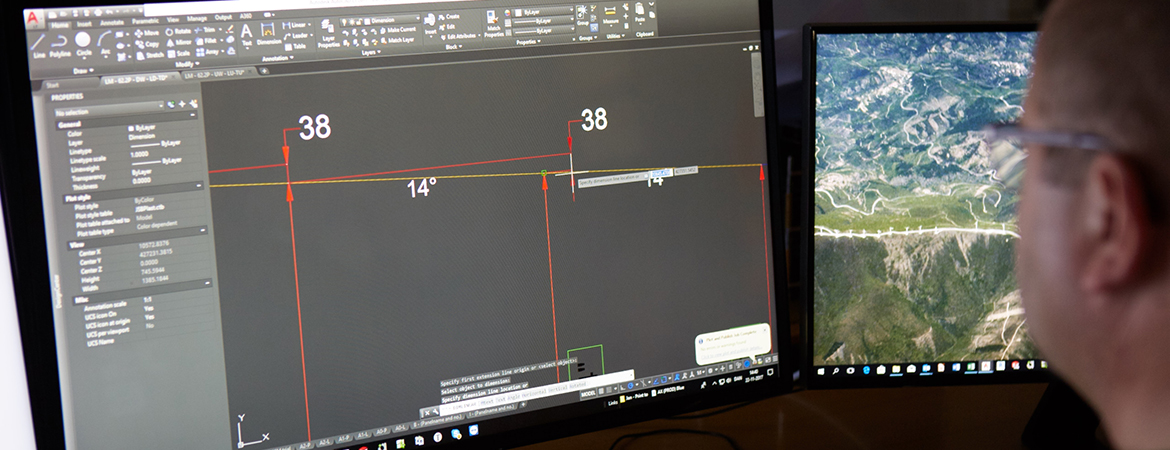

We strive to reduce complexity, from initial design, prototyping and in-house production to final delivery and ongoing support, including on-site lay up support.

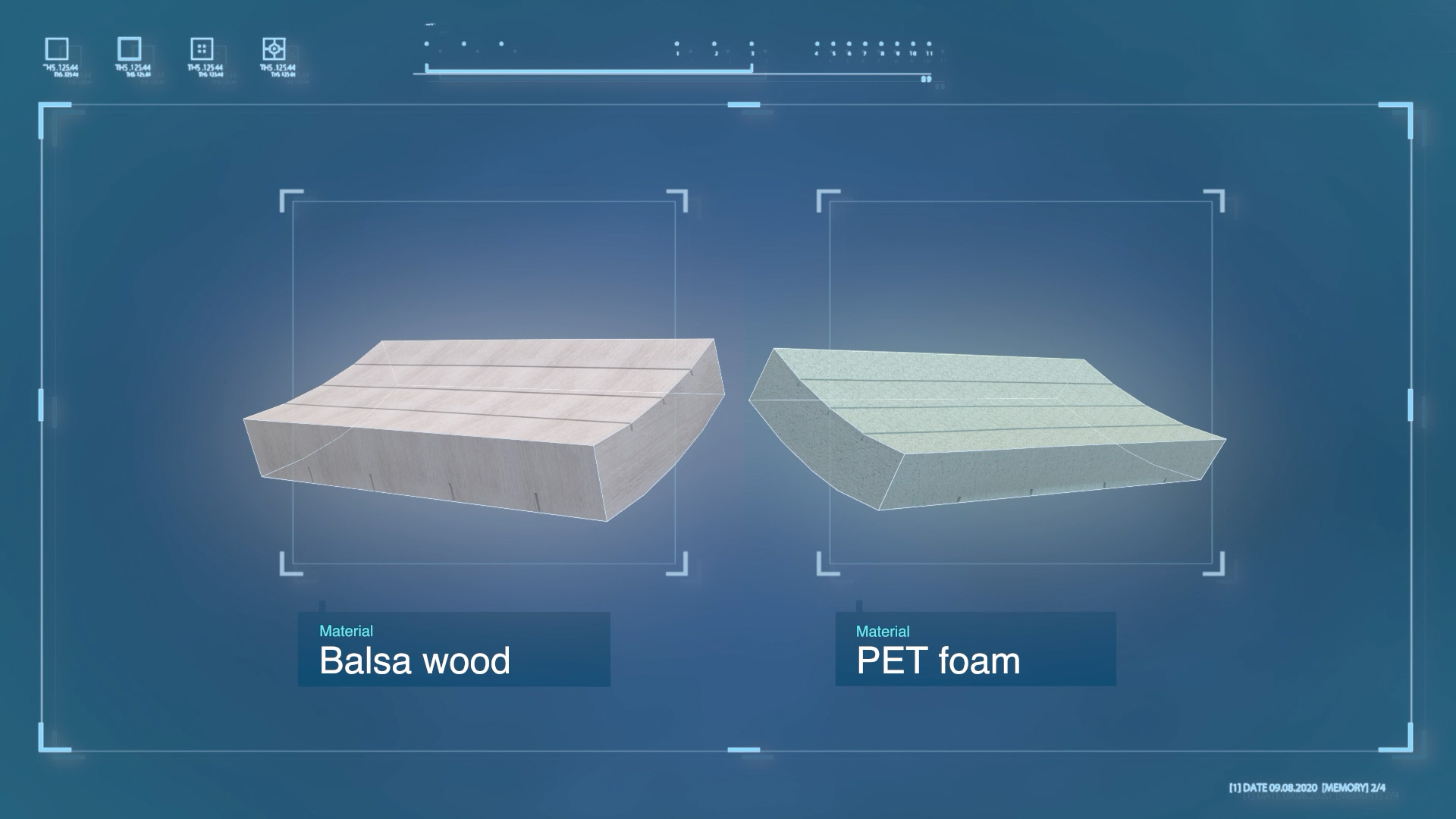

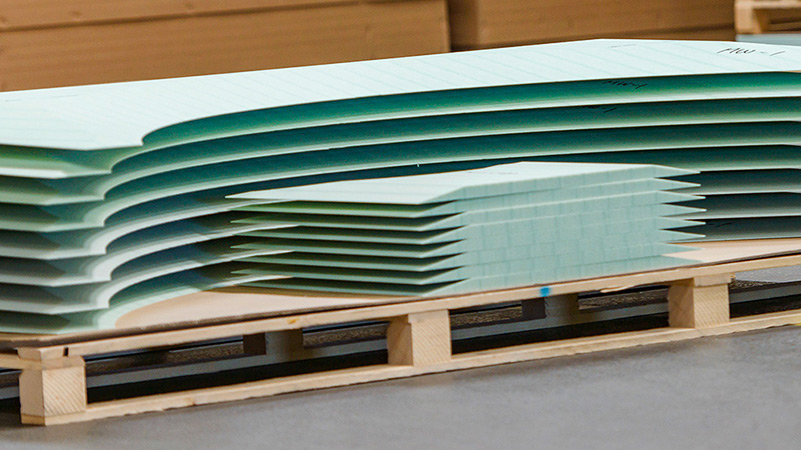

Core material kits consist of up to 1600 unique items used to increase the durability and performance of wind blades. By combining the right thickness and sizes and cutting them into precise shapes, a kit becomes a lightweight yet sturdy component to support the wind turbine blade.

We understand that wind turbine manufacturers operate in an industry with very little room for error, and so, all aspects of our processes are calibrated to the finest detail for consistent quality. Our global sites all hold ISO Quality Management System certificates.

A flexible approach

As the biggest core kitter worldwide, we build our know-how on long-lasting relationships with market-leading turbine manufacturers.

Combined with our specialized technical knowledge of the kitting process, we can help with choosing the best core material and supplier to achieve maximum cost-competitiveness, whilst ensuring full cost transparency.

To lower Levelized Cost of Energy, the wind energy industry relies on OEMs to produce larger blades, which in turn complicates the associated logistics. Our global sites are positioned in close vicinity to blade manufacturers, reducing both logistics and related costs. We draw on our experience with blades and an in-house engineering unit to form new solutions as turbines are getting more complex.

We know that the aerodynamic shape of the blade demands high precision, so each project undergoes a thorough prototyping process until the product fits perfectly into your blade. Finding the right balance between a short development cycle and optimization of the prototype is of high priority to us.

More information about our Wind Energy Solutions

You want to know more about Gurit's offering for the Wind Turbine Industry? Our experts will be happy to support you.