News

Sailing Toward Sustainability: Reducing the Environmental Impact of Race Boat Construction

For decades, race boats have been at the cutting edge of marine technology. They are built to test the limits of speed, strength, and endurance, where every gram counts and every design decision is scrutinised for performance gain. Many of the composite solutions now common in commercial and leisure boats were first proven under the pressure of competitive race boats.

Yet in recent years, the spotlight has widened with sustainability now an increasingly common focus of the racing world. Questions are now being asked about the environmental cost of building these highly optimised vessels and how the race boat community can reduce its environmental impact without dulling its competitiveness.

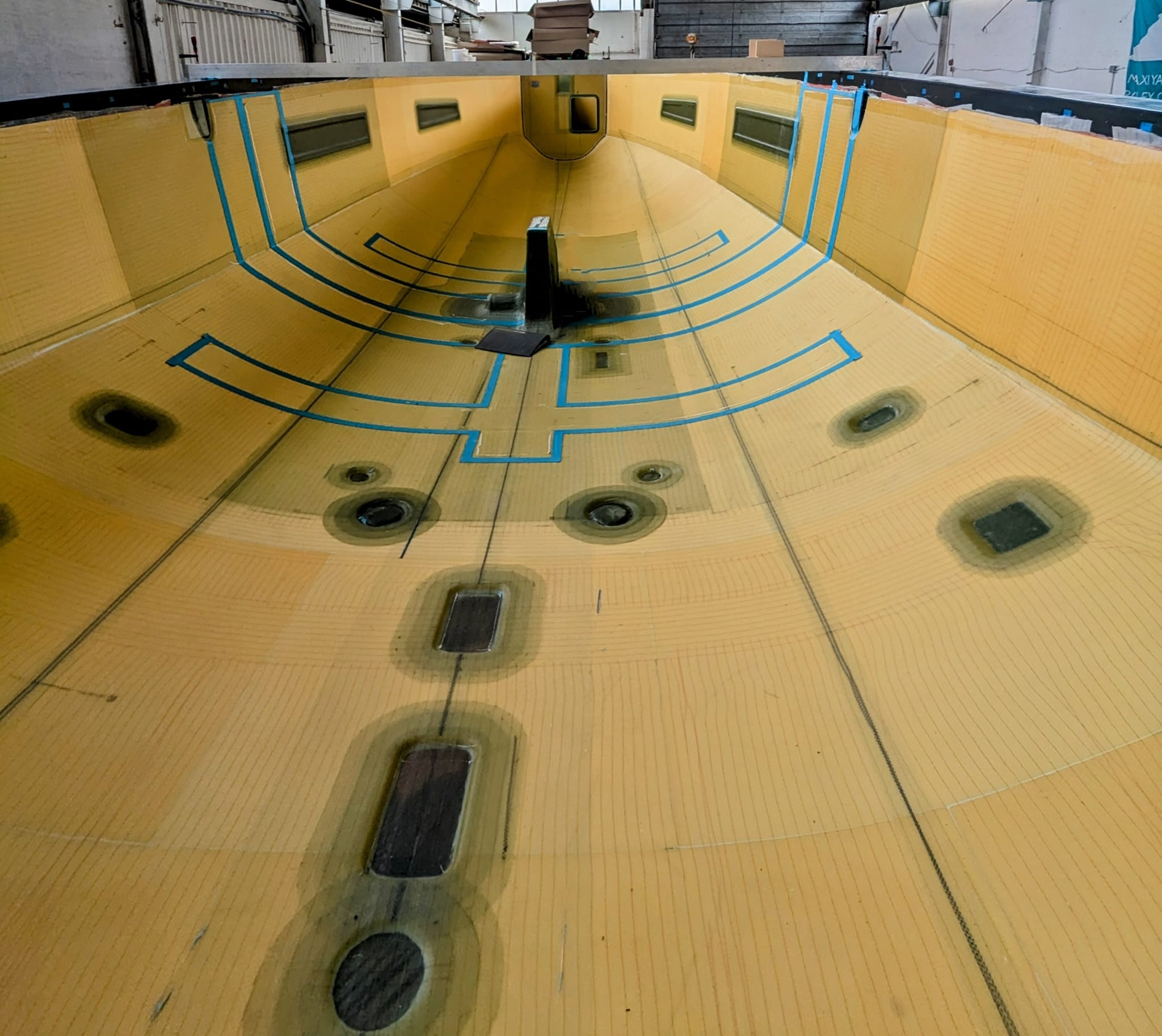

This is where Life Cycle Analysis (LCA) has provided clarity. Studies on new IMOCA builds between 2020 and 2024, from cradle-to-gate, show that more than 75% of the global warming potential, or tCO2eq, comes from materials and tooling. Tooling alone represents 44% of emissions, followed by the hull platform at 32%, with foils, appendages, and rigs making up the remainder. These insights point to very specific areas where change can deliver meaningful results.

The IMOCA Class has already acted on these findings. Since 2024, new builds must comply with a strict CO₂ budget, with penalties for non-compliance. Teams are encouraged to share moulds across campaigns, extending tooling life and reducing the footprint associated with each new hull. A simplified LCA tool has also been introduced, giving designers the ability to quantify trade-offs and select solutions that balance speed, strength, and sustainability. These measures show how technical rules, when well-targeted, can reshape industry practice.

Images © Antoine Auriol / Team Malizia

Beyond construction, other series are turning their attention to impact during the use phase. SailGP, for example, now publishes a detailed Purpose Report each season, tracking not only operational emissions but also progress against longer-term sustainability goals. This level of transparency highlights that the challenge is not confined to the yard floor but also extends across the full lifecycle of competitive sailing.

At the heart of the issue is material choice. Carbon fibre delivers unmatched performance but also carries the highest environmental cost, and the higher the modulus, the higher the impact. Despite this, its benefits in terms of durability and performance can justify its use when applied thoughtfully. At the same time, new options are emerging, including recyclable fibres and bio-based resins, and ongoing research into end-of-life recycling for composites is helping to close the loop. This mix of the old and the new expand the toolkit available to designers, enabling smarter combinations of materials to balance performance and sustainability on a project-by-project basis.

Equally important is the concept of sobriety. This means building fewer moulds, extending the service life of yachts. Practical examples already exist such as Class40 and Multi50 which have rules restricting carbon use, while the America’s Cup has mandated limitations on mould materials. Even keel materials are carefully controlled, showing how class rules influence not just fairness but also sustainability. In fact, while materials like uranium (historically used for its higher density than lead) or even gold (19.28 T/m³, around 1.7 times denser than lead) could in theory make a boat faster, it’s easy to see why such options are unreasonable. Rules prevent these extremes, ensuring competition remains practical, safe, and responsible. By doing so, they reduce both emissions and costs which are crucial components in a sport where budgets and climate responsibility are under equal scrutiny.

What makes these advances particularly powerful is not that race yacht solutions themselves can simply be copied elsewhere, but rather the process of using Life Cycle Analysis to understand where emissions occur and which levers matter most for each application. In competitive sailing, the unique drivers include frequent new hull moulds, high-temperature tooling, and one-off builds. In other sectors, like ferries or commercial shipping, the CO₂ balance is very different with most emissions coming from years of operation, so design trade-offs must reflect that reality. The true trickle-down benefit of the race boat world is learning how to analyse and balance these factors, ensuring that each project finds its own path to reducing impact without assuming that one material or approach is universally good or bad.

At Gurit, we see sustainability as a technical challenge every bit as demanding as performance optimisation. By combining advanced composite materials with engineering expertise, we support teams and classes in balancing the transition of both competitiveness and environmental responsibility, and we believe race boats can continue to lead the way in demonstrating how the marine industry can meet the climate challenge while retaining its competitive spirit.

This article was written by Yoan Stephant, Senior Design Engineer at Gurit, and was originally published in the Composites Association of NZ’s magazine Flexi.

The Shearwater catamaran is one of the UK’s most enduring and technically progressive multihull classes. First designed in 1956, the Shearwater celebrates its 70th year as a class, from cold-moulded timber to today’s full carbon, foam-cored epoxy structures.

That evolution continues with the latest Shearwater racing catamaran built by Zest Boatworks, under the direction of owner and boatbuilder Pete Jary. Built using advanced composite materials from Gurit, the boat represents the cutting edge of Shearwater design while remaining firmly rooted in the class’s rich heritage.

The unfinished boat will be on display at the RYA Dinghy and Watersports Show 2026 on 21-22 February, offering a rare opportunity to see the structure and materials behind a modern high-performance racing catamaran.