Corecell: The Foam That Floated a Revolution

A little over 25 years ago, a pioneer in sandwich construction developed an entirely new linear core that remains unmatched in the composites arena, establishing itself as the core of choice for the most demanding of applications.

The history of Corecell foam and its creator, Tom Johannsen, a pioneer of cored construction in North America, is woven into the broader evolution of high-performance composite materials—especially in the marine and wind energy sectors.

Founded in Canada, ATC Chemicals Inc. was originally established as a three-way partnership to produce polyester bonding compounds for the installation of foam core. Under Tom’s stewardship, however, an entirely new formulation of linear foam core based on SAN chemistry became the company’s flagship innovation; and they called it Corecell. Demand increased exponentially from the mid 1990s when it went into limited production.

What gave Corecell its edge? Its proprietary process to foam styrene acrylonitrile (SAN) — a material that outperformed its competition in thermal stability, chemical resistance, and mechanical toughness. Its introduction was timed perfectly for designers and engineers who were searching for alternatives to PVC foam and balsa wood.

What Is Corecell SAN Foam?

Corecell is a structural foam core material based on SAN chemistry, developed specifically for lightweight sandwich construction—a method used widely in high-performance boats and wind turbine blades.

Key benefits include:

- Outstanding impact and fatigue resistance

- High shear and compression strength

- Low resin absorption

- Unmatched toughness

- Excellent machinability

- Outstanding thermal stability—ideal for prepreg and vacuum infusion processes

The foam’s controlled cell size and uniform density also makes it easy to process, earning favor with composite manufacturers looking for consistency and performance.

24m Cat SWATH Commerical vessel for servicing offshore windfarms, built by Danish Yachts. The second-generation design, built in 2014, was full carbon fiber/Corecell sandwich construction, infused with Prime 20 LV epoxy resin, with structural engineering by Gurit.

IMOCA 60 Charal Designed by VPLP and launched in 2018 for solo skipper Jeremie Beyou to compete in the 2020 Vendée Globe. Structural engineering by Gurit. Constructed from Corecell, Nomex honeycomb, and SE 84 prepreg.

The Innovation That Changed the Game

ATC set out to overcome the mechanical limitations and processing drawbacks of traditional cores like PVC, PET, and balsa.

The solution, Corecell foam core, delivered a step-change in performance, particularly in demanding marine and wind energy environments—where slamming forces, water ingress, and cyclic loading push materials to their limits.

Early product lines like Corecell A-series and T-series quickly gained traction for their balance of strength, toughness, and processability.

A Strategic Acquisition and Global Expansion

However, PVC remained dominant, backed by big players with low costs, while PET foam was rising as a cheaper, recyclable alternative. Producing SAN foam at scale was technically complex and capital-intensive, and ATC needed to scale up to compete. ATC took the plunge and broke ground on a new site for a bigger plant, but the timing could not have been worse: it was 11th Sept 2001 (9/11). The immediate decline in demand in the marine and wind energy sectors, combined with cost overruns in the construction of the new factory, led to financial struggles for ATC.

But the new technology was too valuable to let it fade away. ATC was acquired by SP Systems, a UK-based composites specialist seeking to add advanced core materials to its portfolio. This move gave Corecell an immediate global reach and well-supported production capacity.

Tom Johannsen retained the original bonding compound business and the ATC name and re-established financial viability. You can read more about Tom’s legacy here.

Soon after the ATC acquisition, SP Systems was acquired by Gurit Heberlein. Under Gurit’s wing, Corecell not only survived, it thrived, with refined product variants like M, I, and S series entering the market, tailoring Corecell for large-scale marine, wind, and subsea applications.

Today, Corecell stands as a unique high-performance core in Gurit’s portfolio, complementing its PVC, PET and balsa ranges, and still an unmatched core of choice for demanding applications.

The Shearwater catamaran is one of the UK’s most enduring and technically progressive multihull classes. First designed in 1956, the Shearwater celebrates its 70th year as a class, from cold-moulded timber to today’s full carbon, foam-cored epoxy structures.

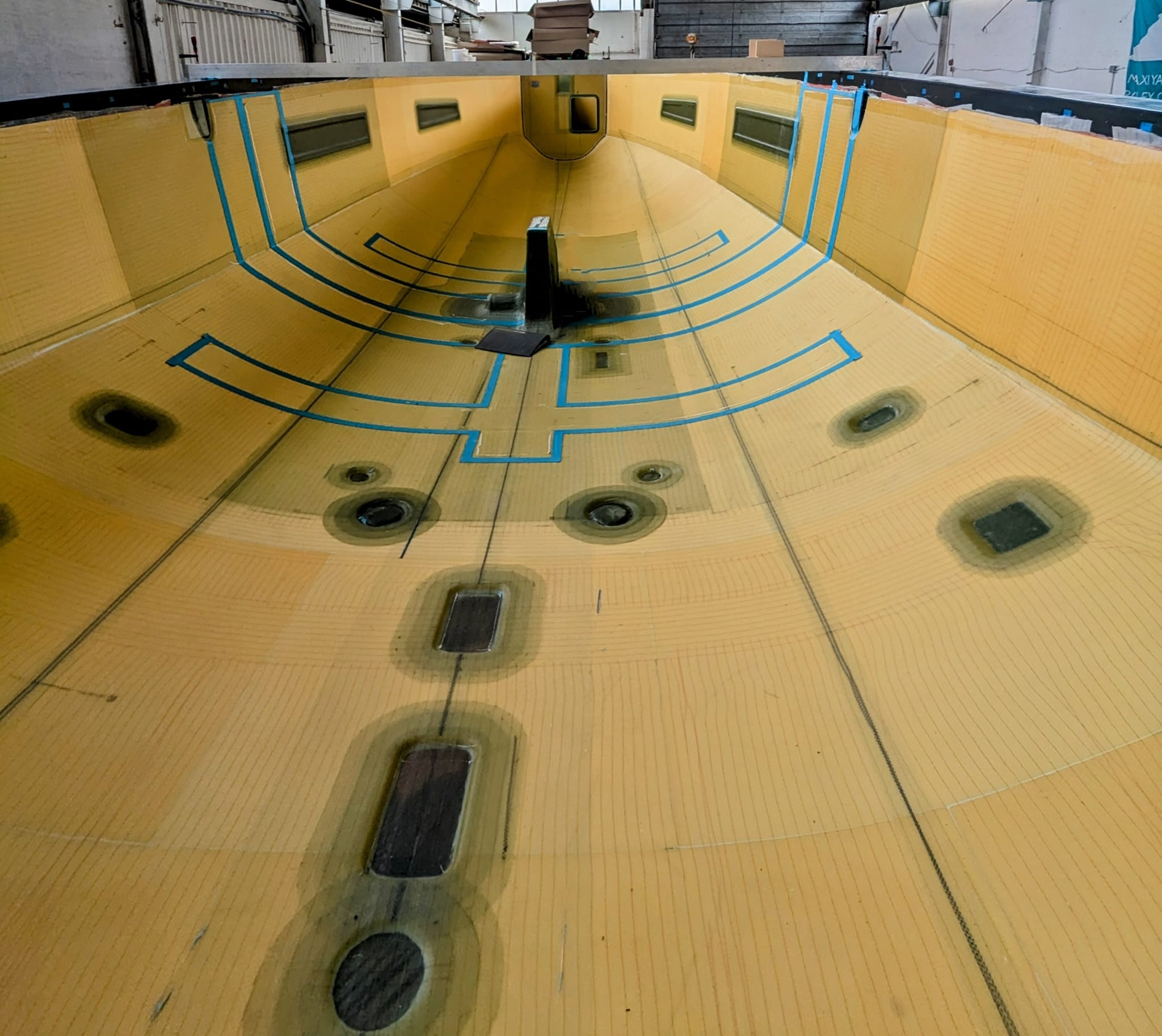

That evolution continues with the latest Shearwater racing catamaran built by Zest Boatworks, under the direction of owner and boatbuilder Pete Jary. Built using advanced composite materials from Gurit, the boat represents the cutting edge of Shearwater design while remaining firmly rooted in the class’s rich heritage.

The unfinished boat will be on display at the RYA Dinghy and Watersports Show 2026 on 21-22 February, offering a rare opportunity to see the structure and materials behind a modern high-performance racing catamaran.