GURIT® CORECELL™ M

THE MARINE FOAM

- High performance foam, ideal for marine applications

- High chemical resistance

- Low resin absorption

- High temperature processing (prepreg compatible)

- Good compressive strength and stiffness

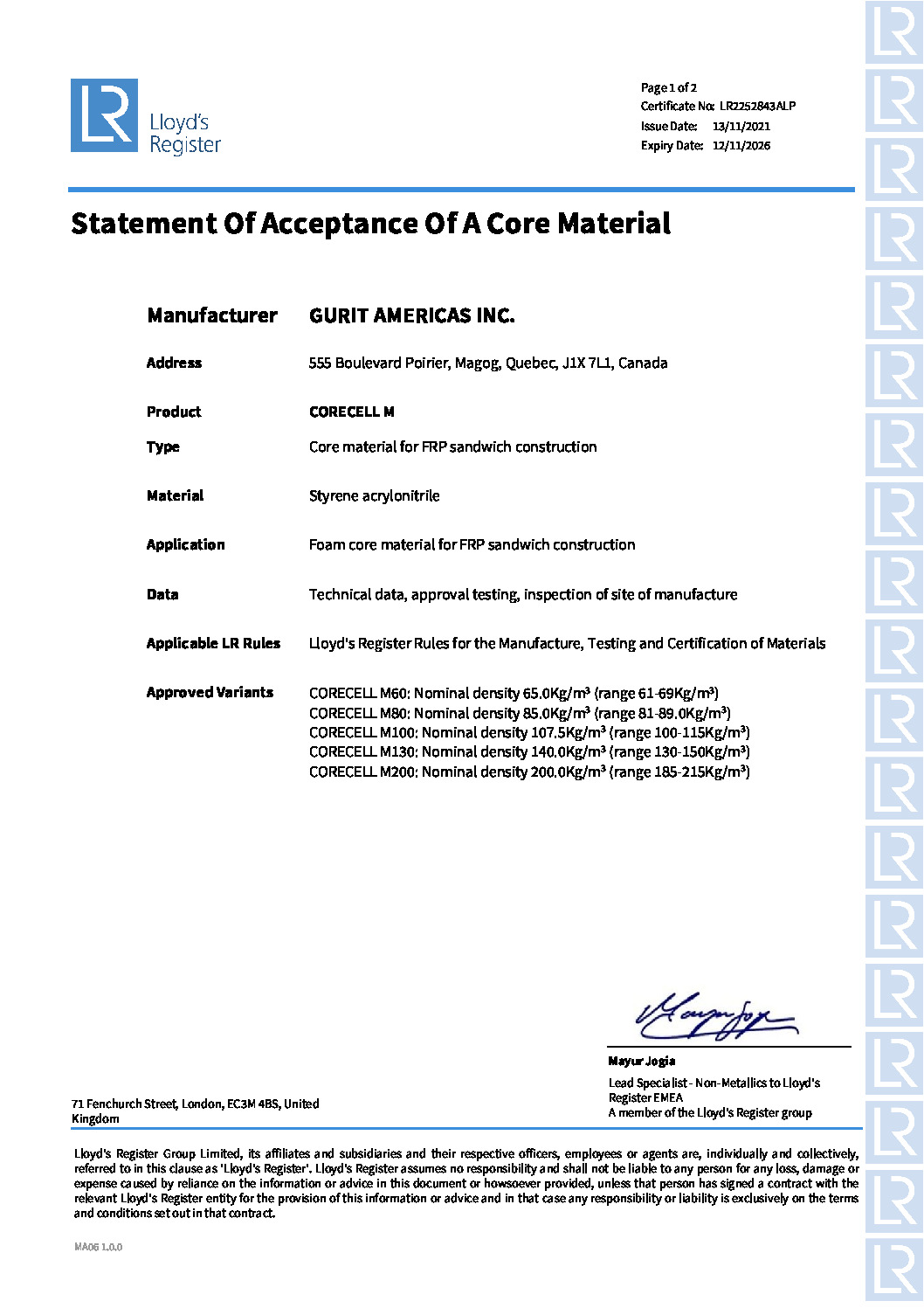

- DNVGL, RINA, BV, Lloyds and ABS certification

- High shear strength & elongation

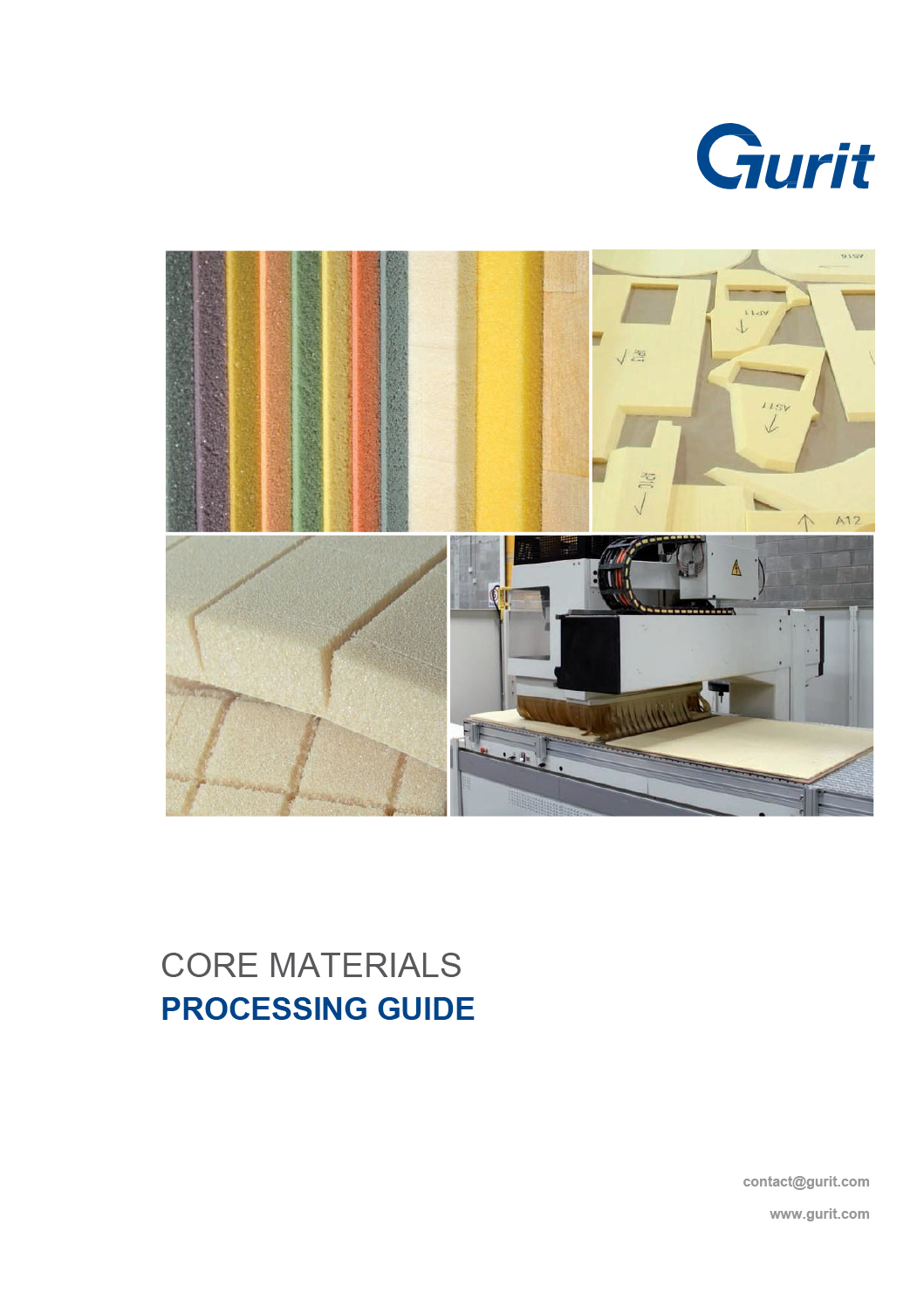

Gurit® Corecell™ M is a structural foam core material using a SAN polymer base featuring high toughness and impact resistant characteristics. It offers very reliable processing without outgassing for high quality parts. Gurit® Corecell™ M shares the benefits of SAN chemistry common to all Gurit® Corecell™ products.

Typical Applications

Gurit® Corecell™ M has been developed to deliver one product for all marine applications. It provides a combination of high shear strength with low density, high elongation, high temperature resistance and low resin uptake. Gurit® Corecell™ M is the perfect choice whether your application is slamming area or superstructure, hull or deck, using hand lamination, infusion or prepreg.

Gurit Composites for High Performance Boat Projects

Case Study

Tool-less composite builds

When Paul Dijkstra Composites began the build of Leonardo Yachts’ new Eagle 46 sailboat, a decision was made to try new approaches to sustainability and efficiency. Dijkstra approached Curve Works, a leader in adaptive mold technology.

Curve Works created a 3D Core Kit of thermoformed Corecell™ M foam core, which then served as the basis for the lamination of the inner and outer carbon structure, while reducing lead time and tooling waste.

Case Study

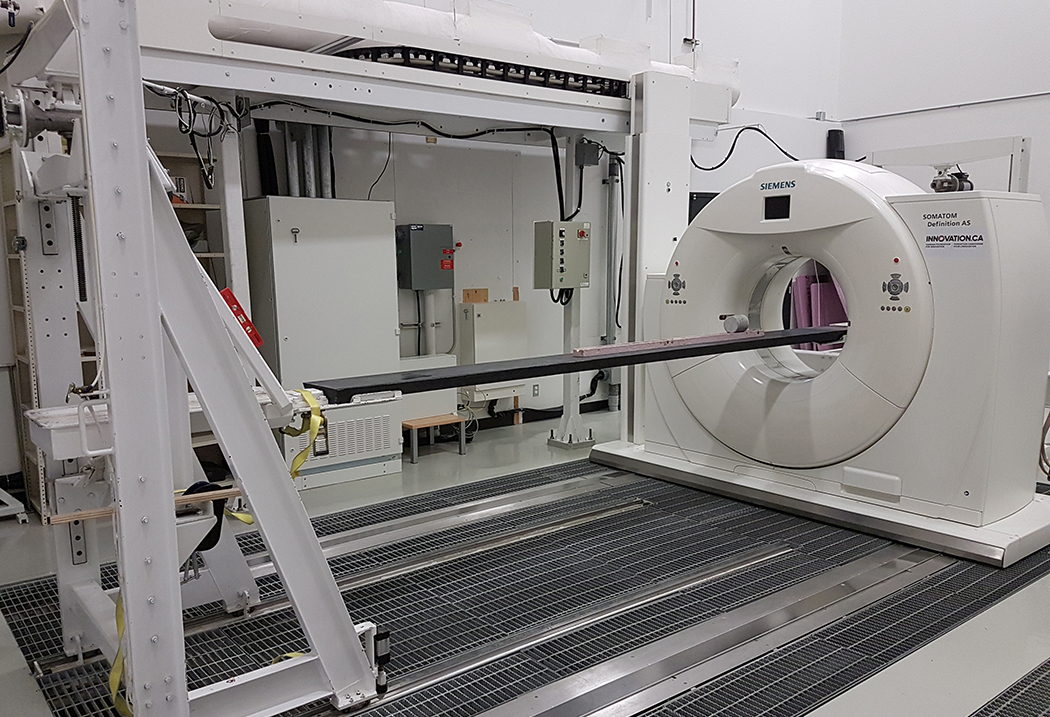

The Centre de Development de Composites Du Quebec (CDCQ) in collaboration with the students of CEGEP Saint-Jerome were set the challenge to create a 3.8m long CT scan table for inspection of large parts, up to 70 cm in diameter and 450kg in weight. Guided by the CDCQ, the students chose Gurit Corecell™ for the structural core material to be used in the sandwich structure, due to its rigidity and unmatched dynamic strength.

Case Study

ANTARES CATAMARANS

Antares Catamarans are based in Argentina, and pride themselves on their personalized and exceptional customer service for their yachts. The vessels are currently built by the team at 40 Grados Sur, which has manufactured them since 2010.

Case Study

Maverik International Moth

Case Study

WEBCo Electric Ferry

The southern hemisphere’s first fully electric high speed passenger ferry, Ika Rere, was launched by ferry operator East by West Ferries, in Wellington, New Zealand. It was built by the Wellington Electric Boat Building Company (WEBBCo) and includes a full package of Gurit, Hi-Panels, Corecell™, PRIME resin, and analysis & structural design.

Case Study

Baltic 67 Performance cruiser

Case Study

ESTEBAN SOLAR CAR

The Esteban project is a team of 50 students from Polytechnique Montréal University whose aim is to design and build a solar-powered car every 2 years. Gurit contributed Corecell M60 and M200 to the team’s conception of a highly aerodynamic, lightweight vehicle. The core supplied enabled them to design an aerodynamic carbon fiber envelope that was light, robust, and the desired shape. This weight savings was a major factor in Project Esteban securing first place at the Formula Sun Grand Prix Competition in 2022 and 2023.

Case Study

RAFALE ETS

Rafale ÉTS is a team of motivated engineering students that has developed a foiling Moth for the Sustainable Moth Challenge. The team chose Gurit Corecell™ M foam for the manufacture of the rudder and daggerboard components to achieve the manufacturing and operating performance required for submerged components.