GURIT CORECELL™ I

- Superior compressive and shear performance ratio

- Competitive shear elongation for toughness

- Excellent long term thermal stability

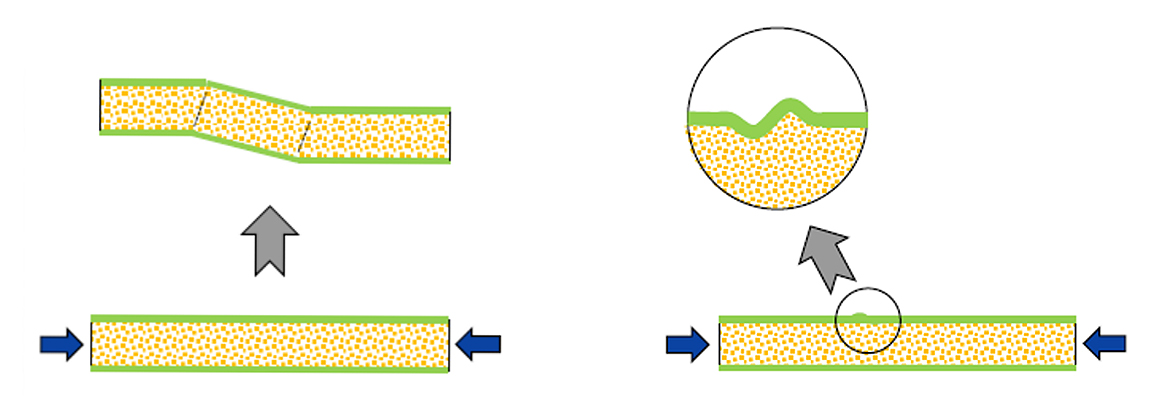

- Homogeneous cell structure and low resin uptake

- Negligible water absorption

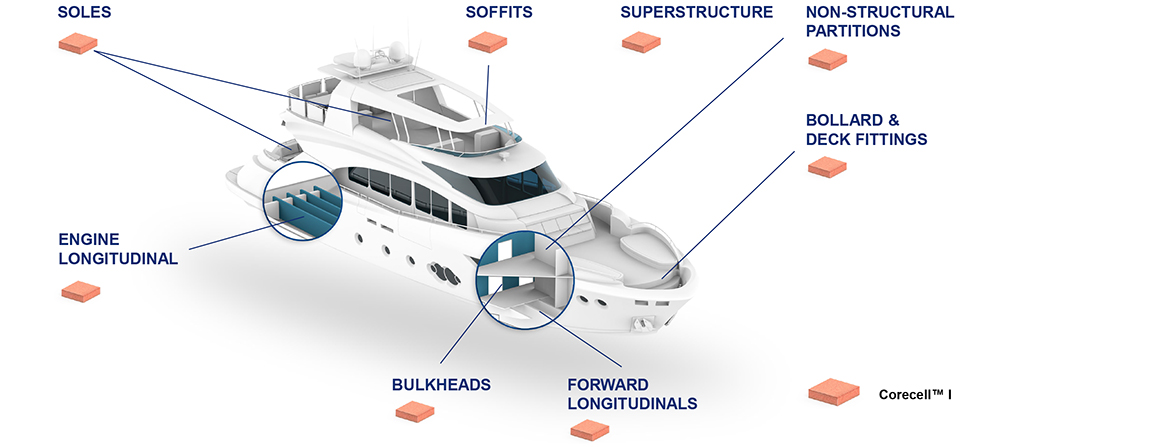

- Suitable for all sandwich composites applications

Introduction

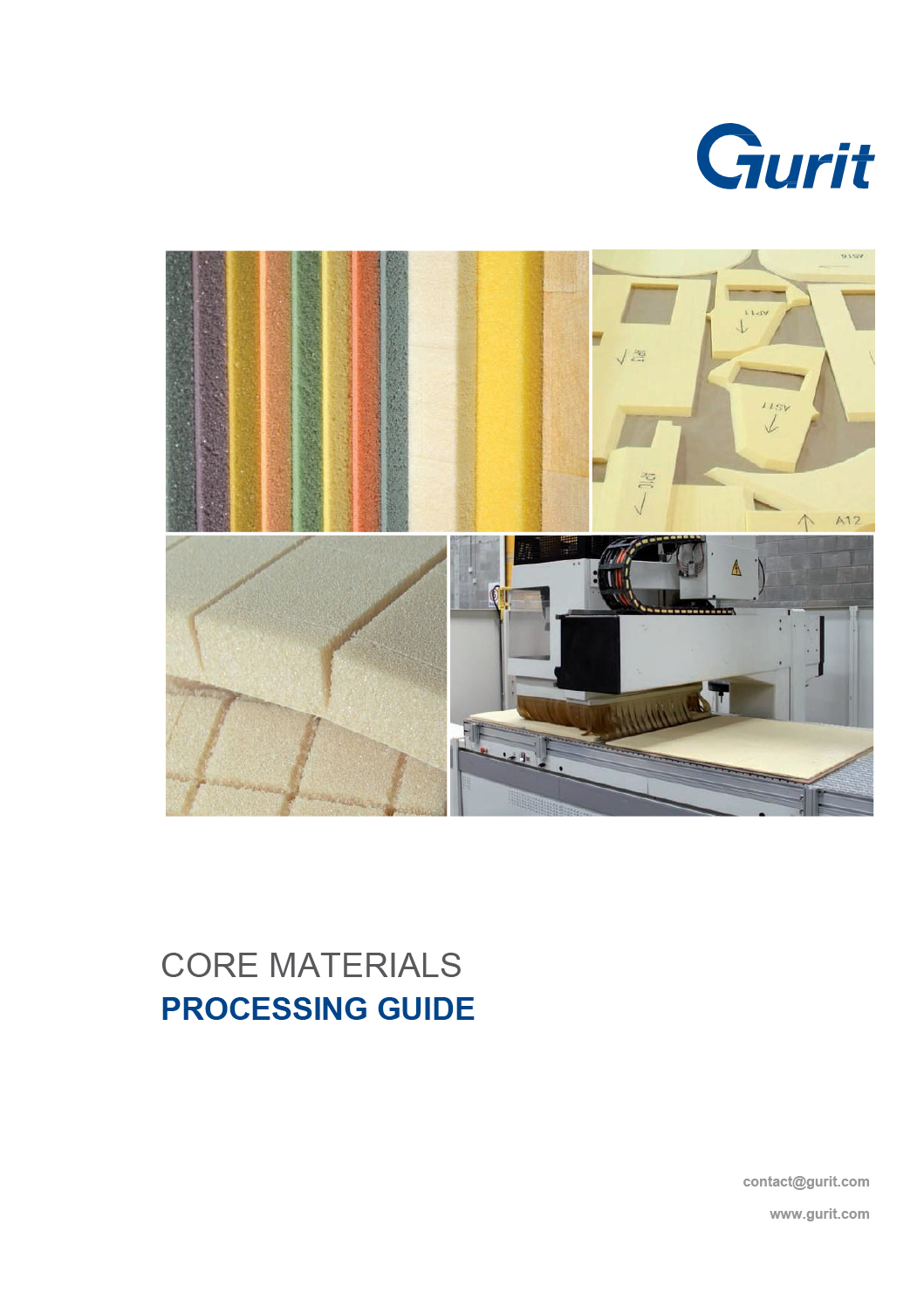

Corecell™ I is a General-purpose SAN core for Marine and Industrial applications. It provides well balanced mechanical properties with high shear modulus and inherent toughness. Low resin absorption and good thermal stability in addition to the excellent handling and finishing.

Product range

Corecell™ I is available in a wide range of densities, thicknesses and benefits from larger sheet sizes than many other core materials, enabling a more efficient kitting process.

Density & sheet size Product

Density (kg/m3)

Sheet size (mm)

Unbonded thickness

I-60

65

1285 x 2605

3-50

I-80

85

1220 x 2440

3-50

I-100

105

1130 x 2275

3-48

Product | Density (kg/m3) | Sheet size (mm) | Unbonded thickness |

I-60 | 65 | 1285 x 2605 | 3-50 |

I-80 | 85 | 1220 x 2440 | 3-50 |

I-100 | 105 | 1130 x 2275 | 3-48 |

Benefits of Corecell™ I

Corecell™ I offers superior stiffness to prevent shear crimping and buckling. It also provides the highest product of CM (Compressive Modulus ) x SM (Shear Modulus), which means that the core can stabilise lighter skins.

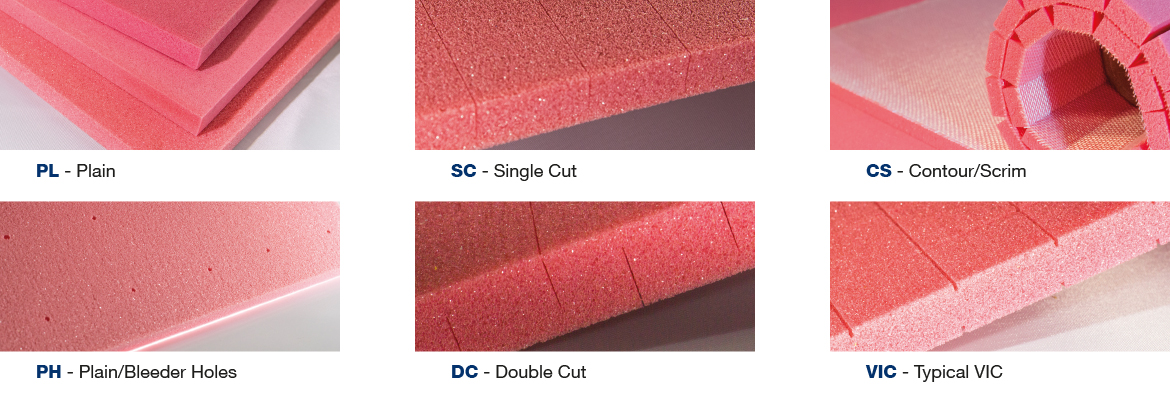

Corecell™ I can be thermoformed and is also available with a wide range of finishing including knife cut.

Product range

Corecell™ I is available in a wide range of densities, thicknesses and benefits from larger sheet sizes than many other core materials, enabling a more efficient kitting process.

Case Study

ANTARES CATAMARANS

Antares Catamarans are based in Argentina, and pride themselves on their personalized and exceptional customer service for their yachts. The vessels are currently built by the team at 40 Grados Sur, which has manufactured them since 2010.

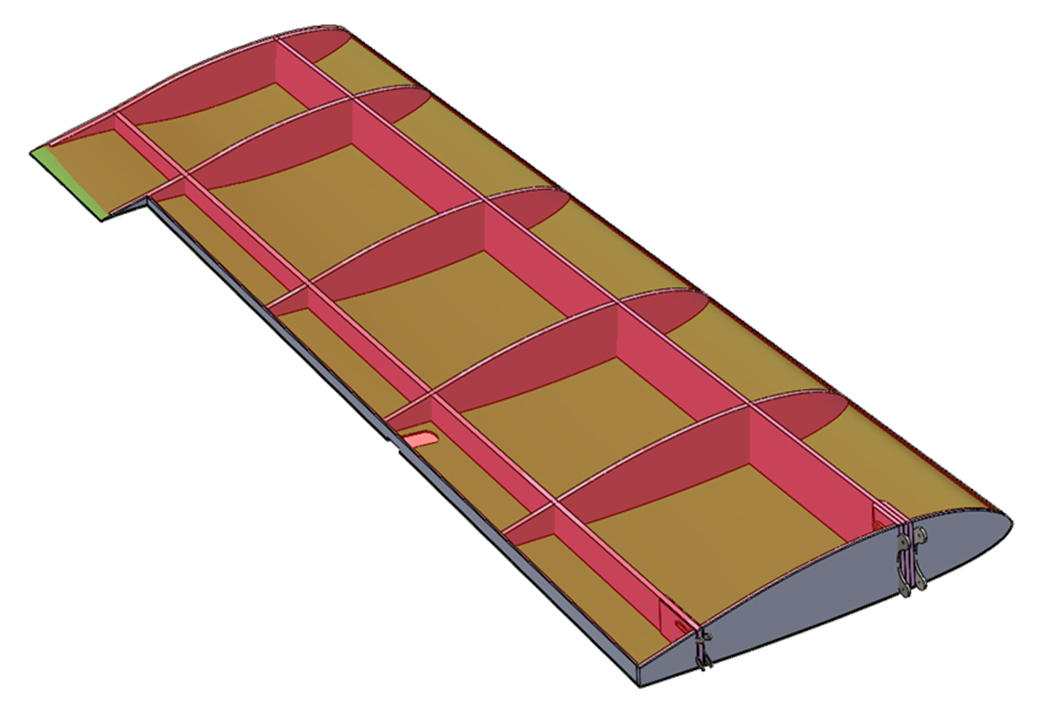

Case Study

beSpline

Case Study

Project Daedalus Composite Wings

University of Sherbrooke mechanical engineering students utilized Gurit Corecell I and Gurit Kerdyn structural core foams in their composite wing designs for KR-2 kit planes.