Australia

Advanced composites & engineering services for Australia

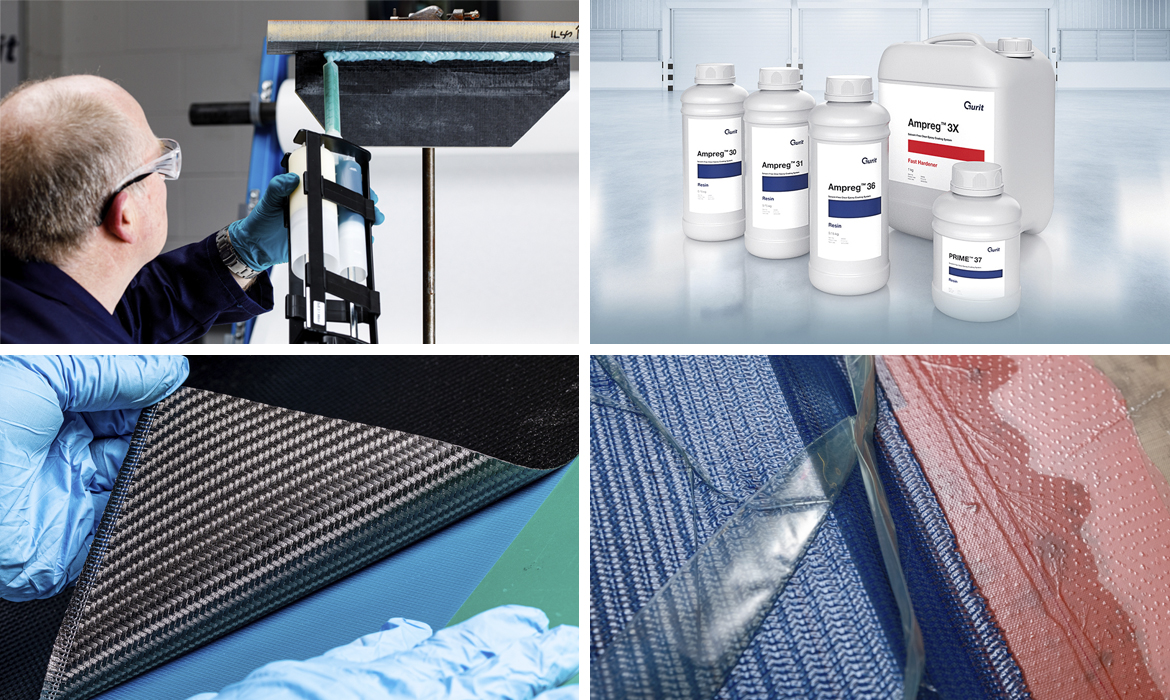

Gurit offers an extensive range of advanced composite materials, solutions and engineering services directly to the Australian composites market for marine, industrial and wind energy applications.

From the Queensland facility Gurit distributes:

- Structural core materials – Kerdyn™ PET, Corecell™, PVC

- Prepregs

- Epoxy resins

- Epoxy adhesives

- Carbon and glass reinforcements

- Vacuum consumables

- Cutting services is offered for reinforcement fabrics

- Gurit kitting services available

Reinforcements & Consumables

All fabrics and consumables will be available in cut lengths with MOQs starting at 5 lineal meters.

- Carbon reinforcements, woven, uni-directional and multi-axial

- Vaccum & infusion bagging materials

- Fibreglass

- Aramid fibres

- Aerovac consumables, breather fabrics, vac films, release files, sealant tapes, flash tapes, heat shrink tapes spray adhesives.

Orders & Deliveries

- Orders can be placed via contacting our customer service team

- Orders received by 10am (AEST) will be despatched same day

- All cash sales orders must be prepaid prior to delivery

- Direct deliveries from warehouse to customers across Australia

- Pick ups are subject to prearrangement only, prepayment required

- No ‘walk in’ sales permitted

- Please refer to the Gurit Product Catalogue AUNZSEA version for a full list of products including availability in Australia.

Gurit Products and Services

For all product information on the standard Gurit product range please refer to the global Gurit website for product pages including technical information and download. Gurit’s range includes structural core materials, prepregs, formulated products; adhesives, liquid and filled systems and reinforcements.

Gurit Hi-Panels, structurally engineered composite panels for custom builds are also available in Australia.

Markets and industries we serve in Australia:

- Industrial including architectural, construction, infrastructure, mining and transportation

- Marine; high performance racing, commercial and work boats, pleasure and sporting equipment

- Rail sector

- Wind energy market including repair systems

Gurit Track Record in Australia

Gurit has a history with many long-standing clients, partnerships and composites projects across Australia. Typical examples include the boatbuilding industry, architecture and civil engineering where advanced composite materials enable innovative lightweight solutions.

Case Study

Riviera, Queensland 4209, Australia

Australia’s premium luxury motor yacht builders use Gurit structural core materials throughout the range.

Case Study

Helitak FT4500 Black Hawk – Fire Tanks

The top section of the tank is constructed from carbon fibre with a Gurit Corecell M foam core, infused with Gurit epoxy resin PRIME™ 27

Helitak chose to partner with Gurit for high quality and consistent supply of composite materials to help combat the growing Bushfire and Wildfire problems our planet is experiencing.

View article in Gurit SHAPE #20 page 12 – 13

Case Study

LINER, COMPOSITE SANDWICH PANELS FOR TRANSPORTATION

Liner supplies Australia and New Zealand’s leading vehicle manufacturers with superior composite sandwich panel and thermal insulation materials for optimum vehicle production, incorporating Gurit’s Kerdyn™ PET as a high-quality structural core component.

Contact Luke Davies at: sales@linersupply.com

Case Study

Maritimo R30 XCAT Offshore Powerboat

“Gurit’s composite solutions were the optimum choice of product for the construction of our next generation Maritimo R30 for 2022 UIM XCAT World Championship competition. Gurit Corecell™ M has provided us with a proven core solution which we felt maximised strength whilst minimising unnecessary weight”.

Tom Barry-Cotter, Maritimo Designer and driver

Case Study

Sykes Rowing boat shells

Sykes has been producing world class rowing shells since 1966 and is one of the few rowing boat builders to successfully transition from wood to composite materials which happened in the mid-90’s. Nowadays, all Sykes mid-tier and premium rowing shells racing boats are manufactured at their factory in Geelong. Sykes boats are widely used by all, from beginners to Olympic Gold Medallists. Gurit supplies Sykes with a wide range of high-quality advanced composites materials including Ampreg™ and PRIME™ resin for use in their boats.

Case Study

100% Zero Emission TP52 Racing Yacht

A restoration project of one of the world’s first elite racing yachts, ‘J-Bird III’. The TP52 yacht has undergone an extensive core refurbishment using a Gurit Hi-Panel, infused composite panel kitset solution and full conversion to electric power with Gurit materials and engineering.

View article in Gurit SHAPE #20, page 18- 21

Case Study

Wild Oats XI

built by Mc Conaghy Boats, New South Wales 2250, Australia

Features Gurit Corecell™ M foam in the hull for excellent slamming performance.

Case Study

Echo Yachts – Charley Western Australia 6166, Australia

The 46m shadow vessel is the largest vacuum infused vessel built in Australia, and one of the largest GRP vessels built in Australia. The vessel, designed by LOMOcean Design is fully foam cored with E-glass and carbon skins supplied by Gurit.

Contact us

Gurit Asia Pacific – Australia Office

Customer Services Team:

Gurit Australia T +61 (0)7 3807 3118 E customerserviceau@gurit.com

Sam Lyon-Jones, Technical Sales Australia

M +61 (0) 474 009 598 E sam.lyon-jones@gurit.com

Daniel Chatley, Technical Sales Representative

M +61 (0) 499 275 586 E daniel.chatley@gurit.com

Tony Stanton, Engineering Manager Asia-Pacific

M +64 (0) 21 853 632 E tony.stanton@gurit.com