Carbon Pultrusion

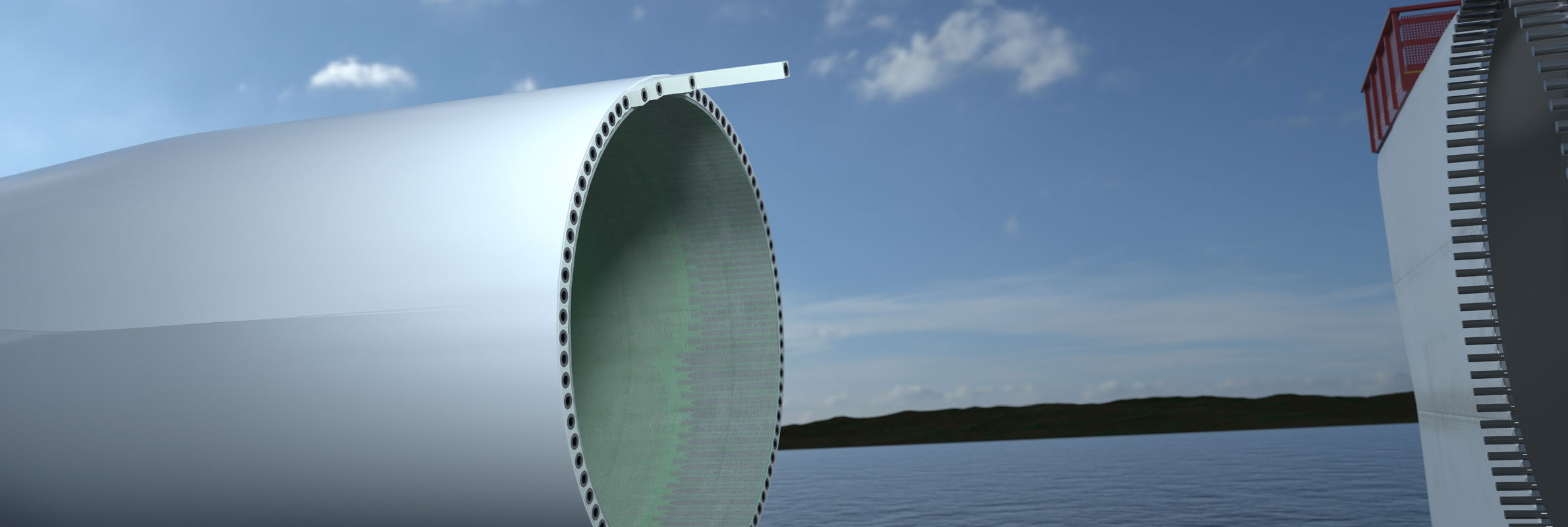

Longer and stronger wind blades

Gurit Structural Profiles’ pultruded carbon fiber profiles help to strengthen constructions in some of the world’s longest wind turbine blades.

PULTRUDED CARBON SPAR CAPS

Gurit Structural Profiles’ pultruded carbon profiles are engineered to purpose and manufactured to fit the specific requirements desired by our customers.

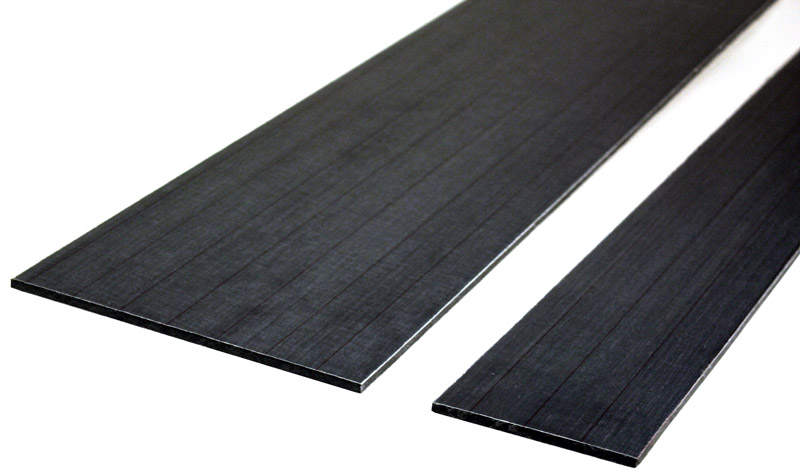

Pultrusion is the most cost effective way of converting carbon fibers into profiles. The continuous process ensures products with a minimum of variation and superior mechanical properties that save significant amounts of material.

Our carbon pultrusion lines run 24/7 and have a capacity of several thousand tons per year.

Choose our carbon pultrusion if you want:

- A versatile supply chain allowing the use of different fibers

- In-house formulated resin systems

- A continuous process with high and consistent quality

- No wrinkles

- Reduced mould time in blade production

- An experienced working partner with a solid track record and processes that meet APQP standards

- Carbon spar caps

Typical properties of our carbon fibers pultrusions:

- Tensile modulus: 130-150 GPa

- Compressive strength: 1200-1600 Mpa

- Compressive strain to failure: 1.0 – 1.3 %

- Density: 1.5 g/cm3

- Fiber volume fraction: 60-70 %