Lightweight composites for Marine

Advanced Lightweighting Solutions for Any Boat Building Project

Gurit supplies advanced composite materials to the full spectrum of marine projects worldwide including industry-leading prepregs, structural core materials, adhesives, coatings, as well as laminating and infusion systems.

The versatility and resilience of Gurit products, coupled with unrivalled in-house technical support and extensive composite engineering knowledge, delivers a solution that is finely tuned to customer requirements, whether that is improved quality, more efficient production, reduced weight or higher performance.

Luxury Yachts

Collaborating with Gurit, superyacht and luxury yacht builders can confidently take advantage of the performance attributes of advanced composite materials.

Commercial and Workboats

The quest for transport efficiency has seen composite materials adopted into most forms of transportation including workboats, ferries or water taxis as operators and users demand lightweight solutions to lower fuel consumption and lower greenhouse gases.

Performance Yachts

For over 30 years Gurit has supplied its proven range of advanced composite materials to numerous race yacht programmes seeking cutting edge performance.

Recreational Vessels

The exceptional performance of composite materials is available to builders of production recreational vessels who are looking to save time in the build process and weight in their finished products.

Composite Engineering

Gurit has offered engineering services to boat builders and designers for over 30 years

A core team of 40 qualified and dedicated composite engineers in the United Kingdom, France and New Zealand supports customers, business partners and projects around the globe with the full range of capabilities tailored to the specific project and needs.

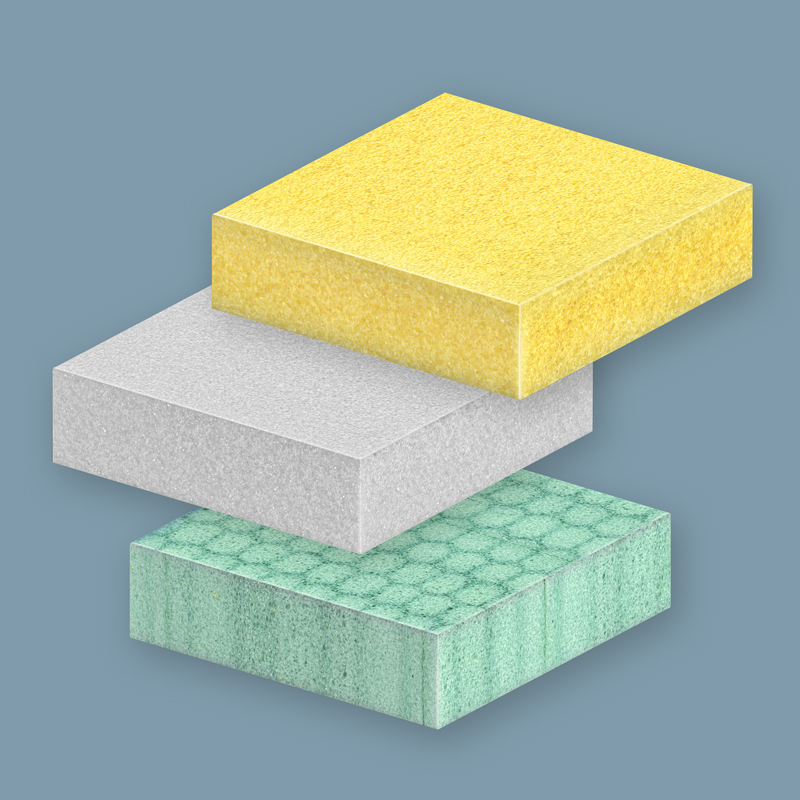

Structural Core Materials for the Marine Industry

PRODUCT RANGE | GURIT PRODUCTS | APPLICATION | CERTIFICATIONS /USP |

SAN | Marine, multi-purpose foam | DNV, RINA, BV, IRS and ABS certified formats | |

For sub-sea buoyancy applications | High ductility and damage tolerance | ||

General-purpose SAN core for Marine and Industrial applications | DNVGL and ABS certified formats | ||

PVC | Suitable for all composite applications | Self extinguishing | |

PET | All-purpose PET foam | DNV certified formats |

Prepregs and Semi-pregs for the Marine Industry

PRODUCT RANGE | GURIT PRODUCTS | APPLICATION | CERTIFICATIONS /USP |

75 Range | Wide range of Marine & Industrial applications | DNV & Lloyds certified Low temperature and fast curing flexibility | |

130 Fire Retardant Range | For components requiring a high level of fire protection | EN45545 | |

90 Range | SE 90 | Suited to very large Marine and Industrial Structures using heavy weight reinforcement | DNV certified |

Epoxy Resins and Adhesives for the Marine Industry

PRODUCT RANGE | GURIT PRODUCTS | APPLICATION | CERTIFICATIONS /USP |

AMPRO™ | Small - medium structures | Bio-based content | |

Ampreg™ Laminating | Small - medium structures | DNV & Lloyds certified formats | |

PRIME™ Infusion | Medium to large structures | Bio-based content as standard | |

Spabond™ Bonding | FR Series | Small to large structures | DNV and Lloyds Register in progress - 400 series |

MORE INFORMATION ABOUT OUR MARINE SOLUTIONS

You want to know more about Gurit's offering for the Marine Industry? Our experts will be happy to support you.

Composite Innovation on Open Water

Case Study

Nauta Tender 48′

A mediterranean project our Structural Engineering team is proud to have been involved in.

Gurit Structural Engineering, Gurit SPRINT™ prepreg; Gurit Corecell™ structural core.

Case Study

Baltic 67 Performance cruiser

Baltic Yachts drew on their 48 years of design and building experience to create a full composite boat, with a glass hull and full carbon deck. Using Gurit epoxy SPRINT™ and Corecell™ M foam, Baltic were able to produce a strong, lightweight structure with a significant performance edge.

Sustainability Report

Creating a Strong Sustainability Platform

Gurit annually reports on sustainability related topics and performance indicators. The Gurit Sustainability Report has been prepared in accordance with the standards of the Global Reporting Initiative (GRI), core option.