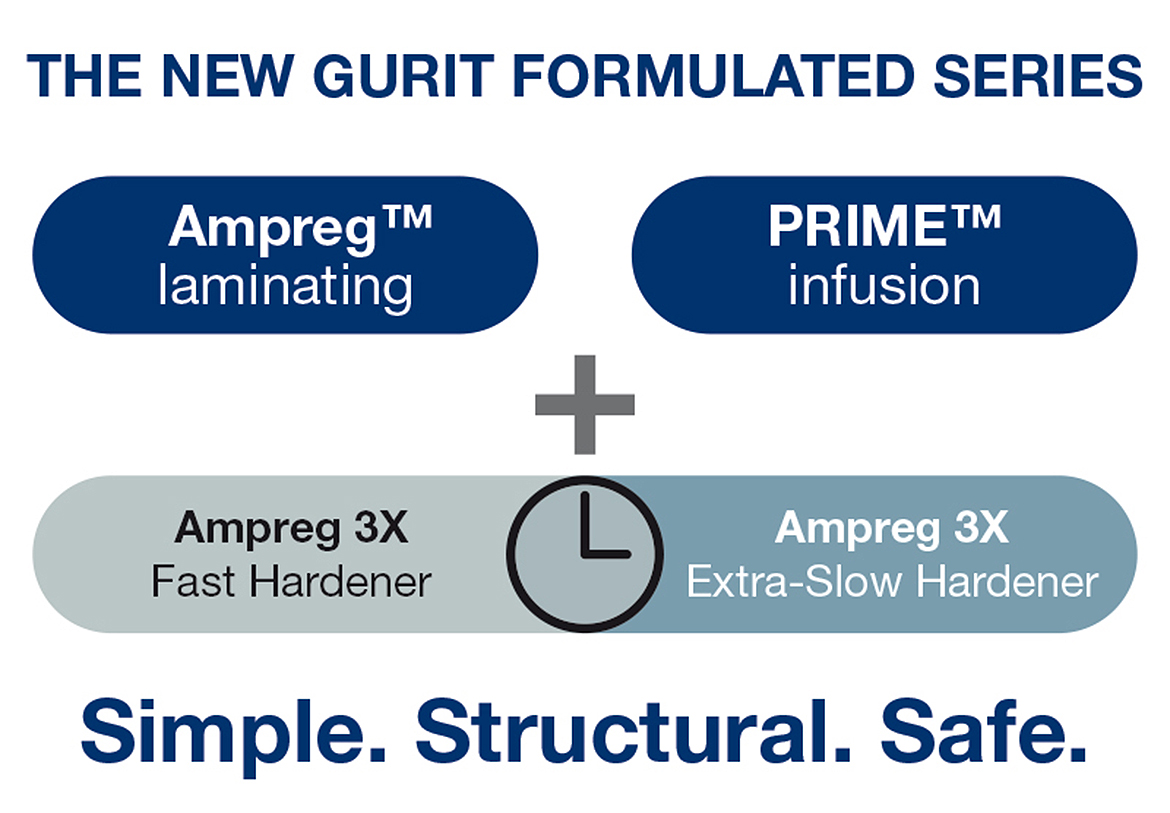

Laminating Systems

The Ampreg™ 3X Series is Gurit’s range of wet laminating systems for the manufacture of large composite structures in the marine, wind and construction industries.

The comprehensive 3X Series portfolio comprises of a single range of low toxicity, blend-able Ampreg 3X hardeners that can be used in conjunction with the following resins:

-

- Ampreg 30 Low viscosity Resin

- Ampreg 31 Drainage resistance Resin

- Ampreg 36 Premium Performance Resin

Additional ancillary products including Thixotropic Pregel Resin and High Tg hardeners are also available.

Product Selector

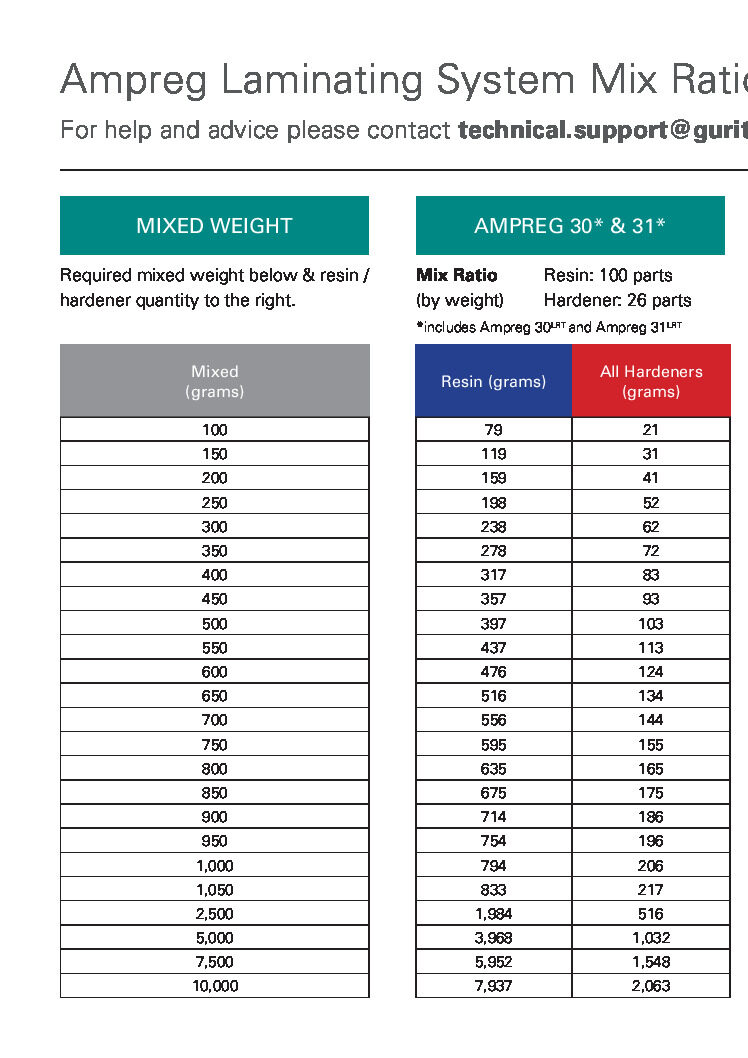

SYSTEM PROPERTIES @ 25OC | DATASHEET | ||

Laminating Systems | Ampreg™ 30 Resin | ||

Ampreg™ 31 Resin | |||

Ampreg™ 36 Resin | |||

Speciality Systems | Ampreg™ 21FR Resin | ||

Ampreg™ 3X AP Resin | |||

Ampreg™ 3X F230-2 Resin | |||

Ampreg™ TP Resin | |||

Health and Safety Focus

The award winning Ampreg™ 3X Series laminating system has been reformulated to prioritise user health and safety through careful selection of base chemicals. The new low toxicity resin matrix is CMR, SVHC and AEP free* and the hardeners are classified as environmentally non-hazardous.

Light Reflective Technology As Standard

Ampreg 30 is available with LRT (Light Reflective Technology) as standard, which serves as a risk monitoring feature for the user and enables inspection of contamination by means of UV light. To learn more about Gurit® LRT technology, please refer to the respective data sheet.