Composite engineering

Structural Composite Engineering

Gurit Composite Engineering provides independent services within the field of Structural Engineering for Fibre Reinforced Polymers (FRP) and Carbon Fiber Reinforced Polymers (CFRP). Our experienced team has been offering independent composite engineering services to designers and manufacturers since the 1980s.

Learn more about our competences:

Key Engineering services

Structural Content Development and Feasibility Studies

- Development of composite structural elements to meet requirements, based upon design briefs of functional, load scenario, or geometrical nature

Laminate architecture design

- Laminate design and optimisation to achieve required mechanical properties for a composite component

Pre-studies

- Quantifying feasibility for new or contemplated composite structures

- Risk assessments (FMEA)

- Mass and cost estimation

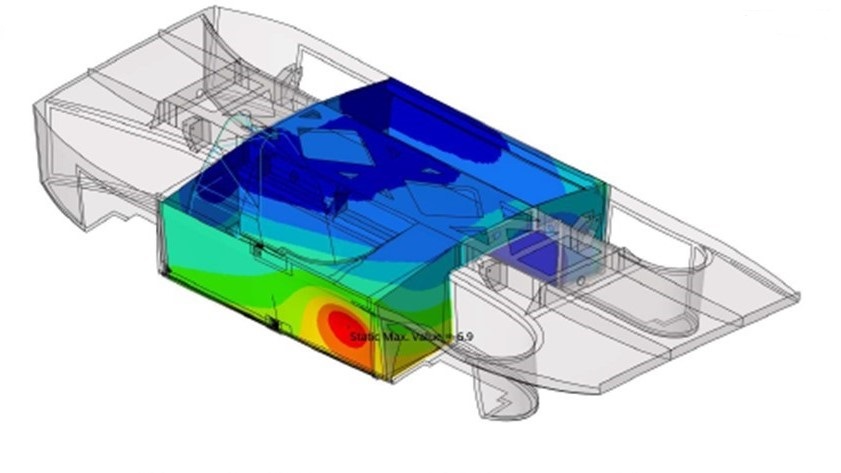

Structural Engineering

- Composite structure detail design and analysis (including FEA)

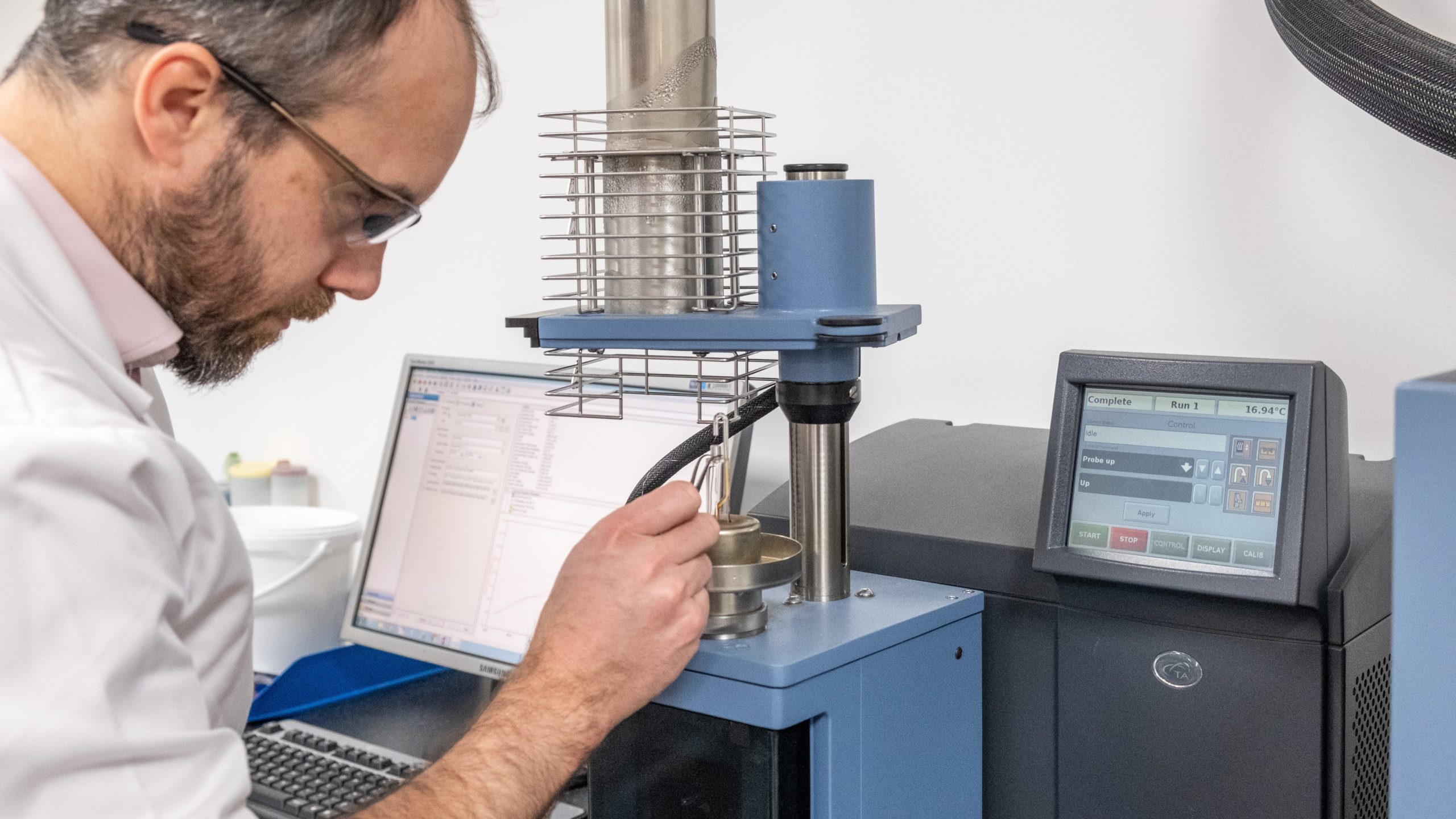

- Material testing and specification

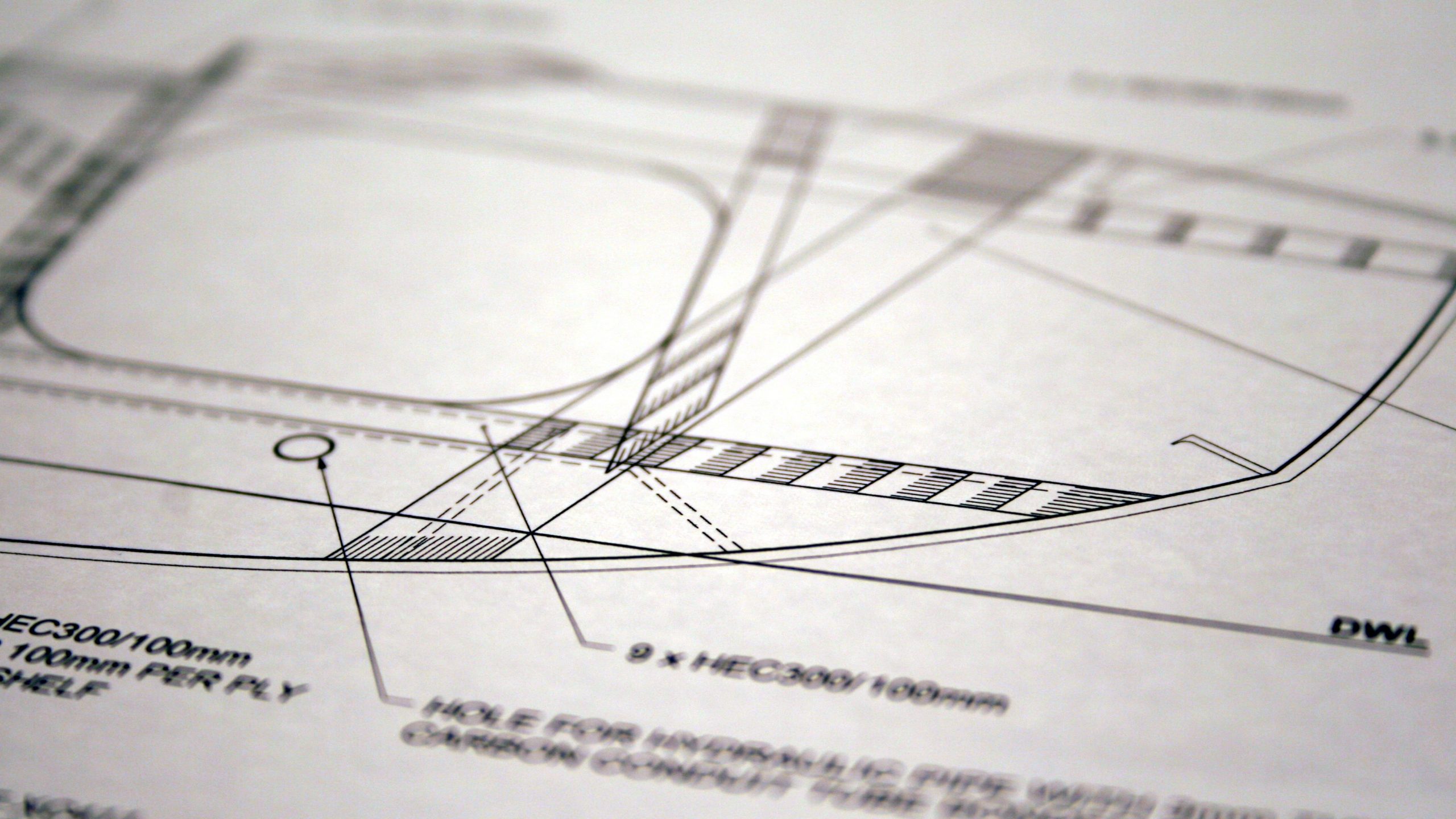

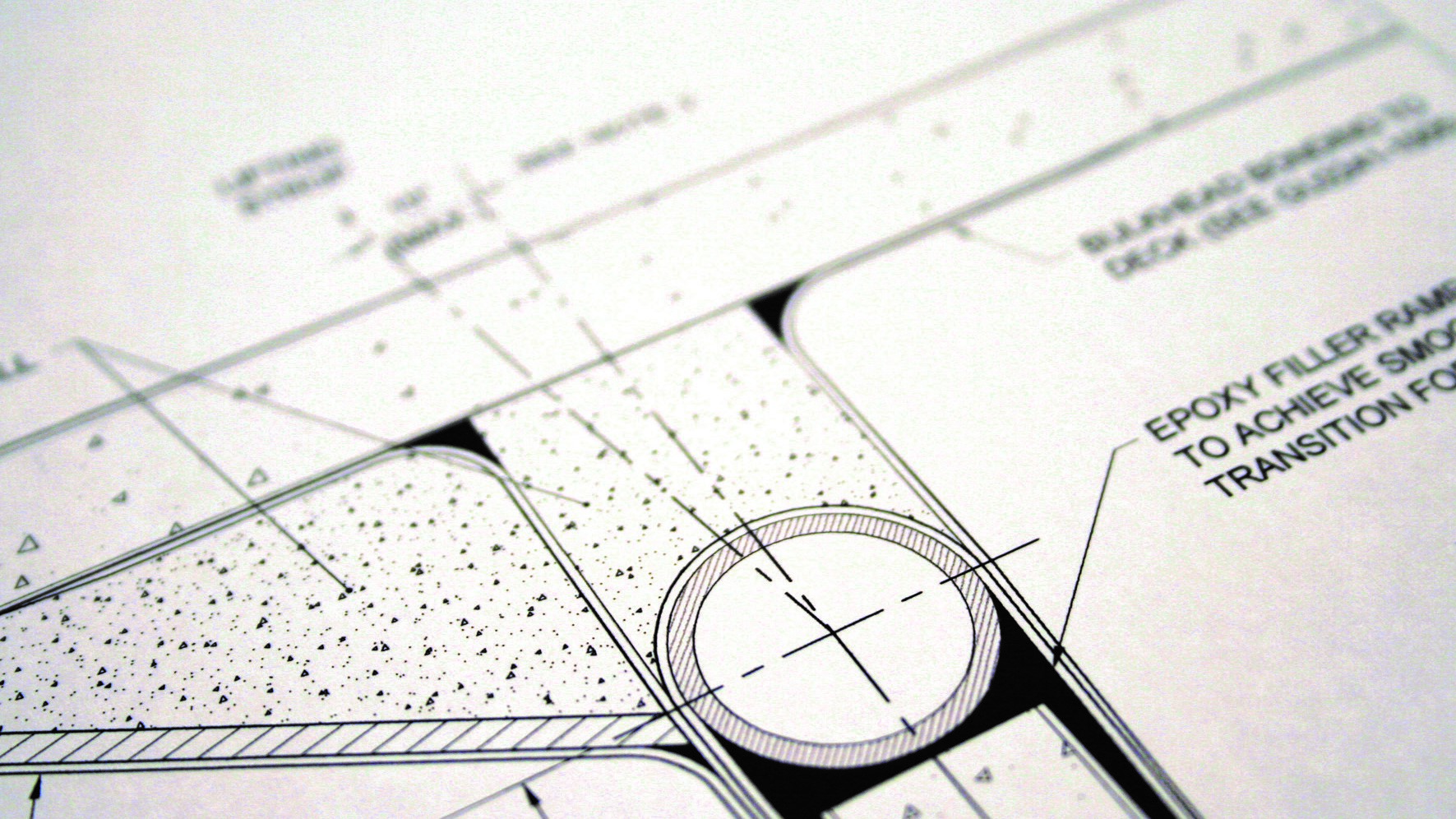

Workshop drawings

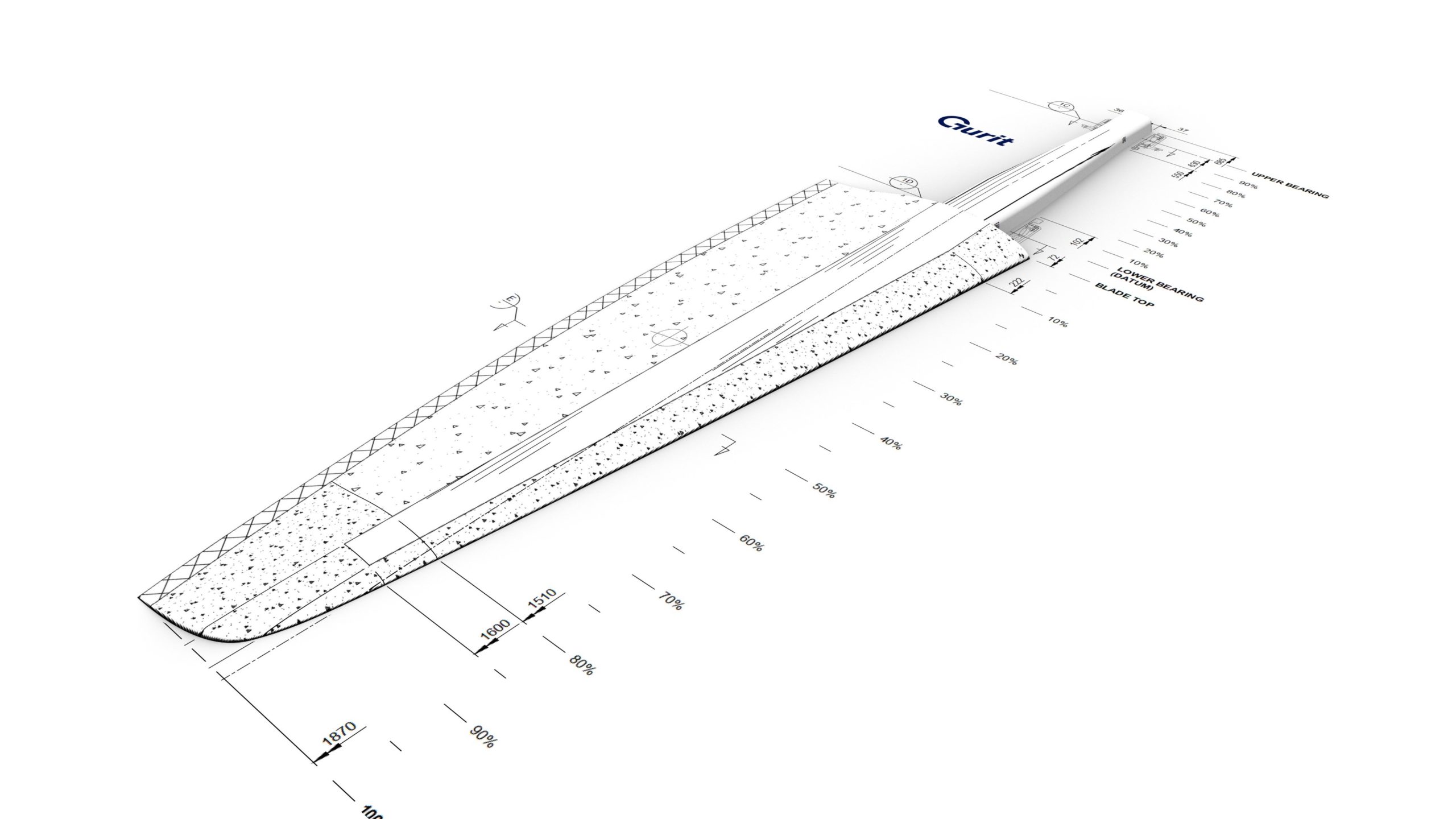

- CAD based draughting service, making laminate drawings, lay-up plans and assembly sequences, as well as 3D computer models and images

Project Engineering Support

- Project management for prototype building at shortlisted and pre-qualified partners, including processing- and quality manuals

- Engineering support during build of composite components

- Classification society and Certification authority liaison

Data acquisition and proof tests

- Post composite part production verification

- Structural monitoring system design

- Load, acceleration and strain data capture, processing and analysis

Trouble Shooting Support

- For engineering and manufacturing

- Testing and evaluation of results

- Composite structure failure analyses and consulting advice

Testing

- Our testing facilities carry independent quality accreditations, and test programs are run by experienced composite engineers

Marine

Working alongside the world’s top boat designers and builders since the 1980’s, Gurit Composite Engineering has helped deliver quality services to the marine field.

We provide an appropriate level of involvement to suit the project needs & budget, ranging from basic advice & design sketches, through to concept studies to full engineering design, 3D CAD, FEA & workshop drawings.

In addition to the main structural design we also design masts & spars, bowsprits & features such as retractable propulsion systems.

Portfolio

Our portfolio includes racing yachts, sailing superyachts, production boats, motor yachts, RIBs and commercial vessels.

For yacht refits we offer initial assessments of the job contemplated, on-site support as well as off-site design and analysis, as appropriate to your project.

Emphasising high quality, use of latest and most efficient design and analysis tools, we work for owners, owner reps and designers, building yards and operators.

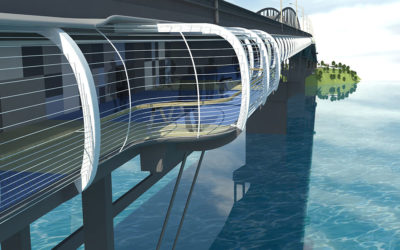

Architectural & Civil Structures

We have delivered FRP engineering for complete roof structures, façades and cladding, houses, urban installations, civil projects, and art sculptures.

We can support if you are looking for some of these features in your project. We offer FRP engineering to architects, consultants and contractors for feasibility studies, as well as to composite fabricators for detail design and analysis.

Advantages sought in architectural and civil application using advanced composites are:

- Light weight for seismic resistance, transport and installation

- Durability, sustainability, low maintenance over lifetime

- Inherently good thermal and acoustic insulation properties

- Vandalism resistance

- Faster and lower cost installation

- Maintenance reduction

- Extended life

- Transport and installation cost savings

- Reduced loads on foundations

- Designable coefficient of thermal expansion (CTE)

- Freedom of form for architectural feature projects

View some of our projects in this sector

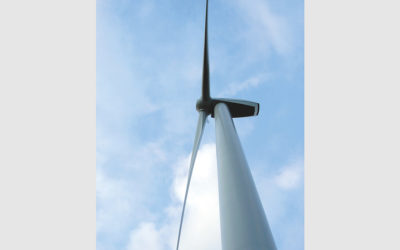

Renewables

Our engineering team offers structural engineering for renewable energy projects in tidal, wave and wind power, from domestic up to multi-megawatt scale.

Gurit designed and built the blades for the first successful and DNV-certified 1MW tidal stream turbine, the Andritz Hydro Hammerfest HS1000, along with many other blades for leading turbine developers. In the marine environment, the main drivers are light weight, fatigue resistance, corrosion resistance buoyancy. These drivers can be met with composite materials but require conscientious engineering and a detailed understanding of the behaviour of materials underwater. Gurit has conducted over 1000 tests on epoxy laminates, adhesives and foam cores under pressure and saturated with seawater to gain this understanding.

View some of our projects in this sector

Industrial & Transportation

Industrial

Composite solutions for an industrial structure can enable new markets and enhance revenues, by letting your product do more for your customer.

The nature of our industrial engineering services means many projects are naturally confidential; however, our track record includes structures and components for goods handling and lifting, farming equipment and flight simulators.

Transportation

With ever more stringent emissions requirements placing additional demands on the design of mass transportation such as buses and rail borne vehicles, as well as automobiles, composites offer a cost-effective route to achieving substantial weight reductions on the load bearing structure of the vehicle. For buses particularly, the use of composites allows payload levels to be maintained or improved whilst accommodating more complex hybrid or electric drivetrains for the same axle weights.

In addition to the potential weight reductions, composites also bring advantages such as improved corrosion and fatigue resistance and reduced part count, which when combined with Gurit’s extensive composite engineering and manufacturing experience can deliver a lightweight structure that integrates directly with the existing vehicle architecture.

Gurit has worked on the global structural design of buses, automobiles, and components for rail vehicle structures as well as the detailed design of components. Our in-depth knowledge of composites allows us to produce robust design details and line-replaceable structural elements allowing easy maintenance in service.

View some of our projects in this sector

Contact our Engineering Team

Paolo Manganelli

Head of Engineering

Europe, the Middle East and Africa and Asia-Pacific

T

Rod Fogg

Principal Engineer

Europe, the Middle East and Africa

T

Tony Stanton

Engineering Manager

Asia-Pacific

T

Steve Shaw

Principal Engineer - Power Craft Leader

Europe. the Middle East and Africa

T

Nicolas Siohan

Renewable Practice Manager

Europe. the Middle East and Africa

T